The Wheelchair Camper Build

Well, I’ve read some great build reports on this site, so its only fair that I add mine as I’ve learn’t a lot from them, as my build is different to almost all as it requires it to be used by me, a Paraplegic, there are a lot of things that I have to do to make it a little easier.

This may help other wheelchair bound people, as there is limited info out there for these types of campervans.

The Vehicle I’ve got is a 3200 KG GVM Mid Roof LWB, 3200kg GVM models are by special order here in Australia, but due to the Side entry Lift weighing in at 140Kg it made sense to up it to 3200kg GVM over the normal 3000kg GVM model here, as it doesn’t take much to overload a camper.

So back to the Vehicle, I ordered the following factory options in July and it arrived in Feb

*Candy White, wanted Pure Grey, but you order a Midroof you are limited to a few colours,… Still white is a better idea for a hot climate.

* Second Battery with Relay Cut-out (cheap option under the seat and frees up space, wasn’t 100% of this when I ordered it, but its there now)

*Reversing Camera (Once you have used these cameras, you can’t go back)

*Composition Media (Not cheap, but has App Connect)

*Interior Comfort Pack (Captain chairs and a heap of extras to make it more than a panel van)

*Appearance Pack (Wanted it look more refined than a panel van, and I hate faded black plastic)

*Wooden Floor and High sided Linings (I will be using them as templates for ply, as I’m not happy with them, I’ll look at sell the factory trims )

The Aftermarket options

*The Braun K90 Lift is mounted under the sliding door with a smaller 70 litre diesel tank as the 80 litre tank won’t work with the lift.

*I’ve decided to get a electric hand break installed, so that will get rid of the issue of lowering the handbrake for a swivel seat and other issues of reaching down to activate it.

Swivel seats for both the drivers and passenger seat, a engineer has installed these, as you are not legally allowed to fit a swivel seat here, unless its done by an engineer and modification plated, Rock n Roll beds are the same, if you want to use them as a seat.

I did my trade as a Cabinetmaker/Shopfitter before my injury and have studied Fine Furniture under a master craftsman for a year and also Residential Drafting at Tech, so I’d like to think I should be able to do a decent quality job, cabinet wise, it won’t be easy, as moving 8x4 sheets of ply is a pain, at least I can break them down with the Festool plunge saw.

I’ve got a small industrial shed to leave the van and work on it, rain or shine, so that’ll help when things are in pieces and not having to put it back together to drive it home.

So now for the spec’s of the build, I’ve had over a year to design what I want, while I’ve be waiting for it to be built and delivered and what I came up with will work for me and my situation, I tend to analyse everything to much.

The Ply will be a 17mm light weight laminated plywood, it comes in at 8Kg per square meter, although I do plan on doing a full scale normal working model mock up to ensure it works for me. I’d rather be able to change the final design than be stuck with a camper that annoys me and I can use it as a template.

I’ll be starting with a angled cabinet behind the drivers seat to allow easier access to transfer into the drivers seat

The fridge is a Waeco CRX65 and a Smev 8000 series sink with glass lid above the fridge, I’ve decided not to install a cooker inside as we cook outside and its not as rainy here, and I hate the way the food smells stay in the fabric.

I decided to use Votronic for the electrics, I have the Votronic Jupiter 100A 12 volt panel, that has solar monitoring, water tank monitoring, USB ports, battery monitoring, inside and outside temp sensors. and under that will be a Voltronic main switch for fridge on/off, 12 volt socket, 4 switches and a blank plate for another switch later on.

The wardrobe will be to the ceiling, and I’m leaning toward sliding doors over tambour doors, haven’t finalized that decision yet and at the end of the wardrobe, ill have a lower integrated cabinets with a retractable shower hose.

The Bed is a 1200mm RIB with 200mm slider option, so I can move the bed mounting frame closer to the tailgate to allow more space, there are two openings to allow for Drawers, so I’ll have a potta potty on a heavy duty drawer unit for the wife and within the drawer space, a divider for toilet paper and chemicals.

As for the roof, I have a Heki 700mm x 400mm Skylight, sitting in the workshop and I just have to make up a timber support internal and a HPDE external mount as the roof is curved, and I’d like to keep the skylight edge parallel and get a good seal.

I have/Had a 250 watt solar panel, but when I opened it on the weekend it was broken and the glass was smashed L I should have opened the box when it arrived a few months ago.. my mistake there, the box was perfect and I didn’t check it at the time, so its too late to get it replaced, at least it was a cheap panel!!

So I will look at getting some semi flexible panels instead, I’ve got my eye on 3 x 110 watt panels as that will work with the Votronic 350 watt solar reg I have lying around.

As for water tanks I have the CAK drivers door and waster water tanks and John Guest hose and fittings sitting there to be installed.

I have 95% of the gear ready to install sitting in the workshop that I’ve been collecting over the last 12 months.

So I better start building it, hopefully it’ll be done before Xmas.

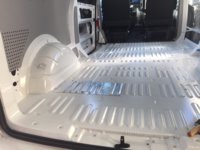

The Van after its trip home from the dealer.

Well, I’ve read some great build reports on this site, so its only fair that I add mine as I’ve learn’t a lot from them, as my build is different to almost all as it requires it to be used by me, a Paraplegic, there are a lot of things that I have to do to make it a little easier.

This may help other wheelchair bound people, as there is limited info out there for these types of campervans.

The Vehicle I’ve got is a 3200 KG GVM Mid Roof LWB, 3200kg GVM models are by special order here in Australia, but due to the Side entry Lift weighing in at 140Kg it made sense to up it to 3200kg GVM over the normal 3000kg GVM model here, as it doesn’t take much to overload a camper.

So back to the Vehicle, I ordered the following factory options in July and it arrived in Feb

*Candy White, wanted Pure Grey, but you order a Midroof you are limited to a few colours,… Still white is a better idea for a hot climate.

* Second Battery with Relay Cut-out (cheap option under the seat and frees up space, wasn’t 100% of this when I ordered it, but its there now)

*Reversing Camera (Once you have used these cameras, you can’t go back)

*Composition Media (Not cheap, but has App Connect)

*Interior Comfort Pack (Captain chairs and a heap of extras to make it more than a panel van)

*Appearance Pack (Wanted it look more refined than a panel van, and I hate faded black plastic)

*Wooden Floor and High sided Linings (I will be using them as templates for ply, as I’m not happy with them, I’ll look at sell the factory trims )

The Aftermarket options

*The Braun K90 Lift is mounted under the sliding door with a smaller 70 litre diesel tank as the 80 litre tank won’t work with the lift.

*I’ve decided to get a electric hand break installed, so that will get rid of the issue of lowering the handbrake for a swivel seat and other issues of reaching down to activate it.

Swivel seats for both the drivers and passenger seat, a engineer has installed these, as you are not legally allowed to fit a swivel seat here, unless its done by an engineer and modification plated, Rock n Roll beds are the same, if you want to use them as a seat.

I did my trade as a Cabinetmaker/Shopfitter before my injury and have studied Fine Furniture under a master craftsman for a year and also Residential Drafting at Tech, so I’d like to think I should be able to do a decent quality job, cabinet wise, it won’t be easy, as moving 8x4 sheets of ply is a pain, at least I can break them down with the Festool plunge saw.

I’ve got a small industrial shed to leave the van and work on it, rain or shine, so that’ll help when things are in pieces and not having to put it back together to drive it home.

So now for the spec’s of the build, I’ve had over a year to design what I want, while I’ve be waiting for it to be built and delivered and what I came up with will work for me and my situation, I tend to analyse everything to much.

The Ply will be a 17mm light weight laminated plywood, it comes in at 8Kg per square meter, although I do plan on doing a full scale normal working model mock up to ensure it works for me. I’d rather be able to change the final design than be stuck with a camper that annoys me and I can use it as a template.

I’ll be starting with a angled cabinet behind the drivers seat to allow easier access to transfer into the drivers seat

The fridge is a Waeco CRX65 and a Smev 8000 series sink with glass lid above the fridge, I’ve decided not to install a cooker inside as we cook outside and its not as rainy here, and I hate the way the food smells stay in the fabric.

I decided to use Votronic for the electrics, I have the Votronic Jupiter 100A 12 volt panel, that has solar monitoring, water tank monitoring, USB ports, battery monitoring, inside and outside temp sensors. and under that will be a Voltronic main switch for fridge on/off, 12 volt socket, 4 switches and a blank plate for another switch later on.

The wardrobe will be to the ceiling, and I’m leaning toward sliding doors over tambour doors, haven’t finalized that decision yet and at the end of the wardrobe, ill have a lower integrated cabinets with a retractable shower hose.

The Bed is a 1200mm RIB with 200mm slider option, so I can move the bed mounting frame closer to the tailgate to allow more space, there are two openings to allow for Drawers, so I’ll have a potta potty on a heavy duty drawer unit for the wife and within the drawer space, a divider for toilet paper and chemicals.

As for the roof, I have a Heki 700mm x 400mm Skylight, sitting in the workshop and I just have to make up a timber support internal and a HPDE external mount as the roof is curved, and I’d like to keep the skylight edge parallel and get a good seal.

I have/Had a 250 watt solar panel, but when I opened it on the weekend it was broken and the glass was smashed L I should have opened the box when it arrived a few months ago.. my mistake there, the box was perfect and I didn’t check it at the time, so its too late to get it replaced, at least it was a cheap panel!!

So I will look at getting some semi flexible panels instead, I’ve got my eye on 3 x 110 watt panels as that will work with the Votronic 350 watt solar reg I have lying around.

As for water tanks I have the CAK drivers door and waster water tanks and John Guest hose and fittings sitting there to be installed.

I have 95% of the gear ready to install sitting in the workshop that I’ve been collecting over the last 12 months.

So I better start building it, hopefully it’ll be done before Xmas.

The Van after its trip home from the dealer.