Genuine Tygon Saint-Gobain F-4040-A Translucent Yellow Fuel Tube - High Quality Low Price! PVC Tube Online Ltd are a specialist supplier of tube and other products. This Genuine Tygon Saint-Gobain F-4040-A Translucent Yellow Fuel Tube is specifically designed to be used as small engine/gasoline...

www.ebay.co.uk

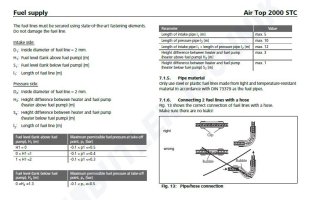

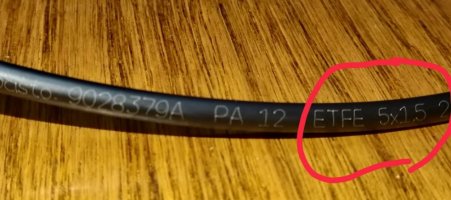

I’m pretty sure I used the 4.8mm ID tubing, it fits all the metal fittings with no need for adapters, I used Oetiker clamps to secure it.

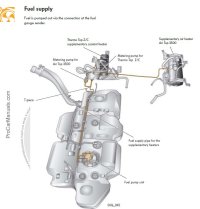

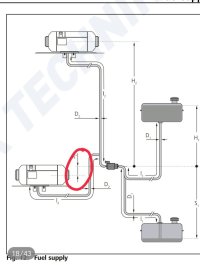

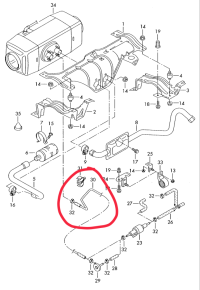

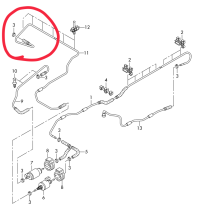

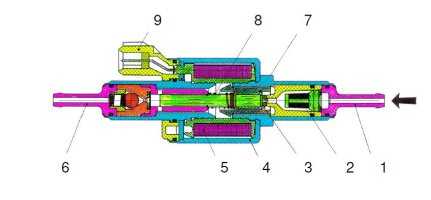

I have been using it in the van installation for a few years now, I made a tank out of aluminium that sits under the rear left corner of the van, about 13 litres, the pump sucks diesel out of the tank via a standpipe tube that pulls fuel from the bottom but fits in the top of the tank, ebay item around a fiver, the pump is mounted just behind the left rear wheel on a soft rubber mount with a Mahle KL15 fuel filter just before it, then the fuel pipe runs across the van under the metal heat shields and down the right hand chassis rail beneath the plastic covers to the heater under the driver’s seat, I have had no issues with fuel delivery to my 2kW heater using this method.