Not quite, it depends on the blow time of the fuse. The max rating for the device is 600W which it cannot sustain continuously and which at 10V is 60A .... the 40A fuse will probably never blow at this current, but it will get hot.

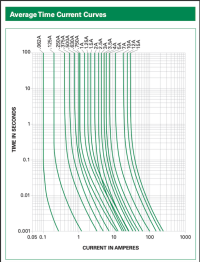

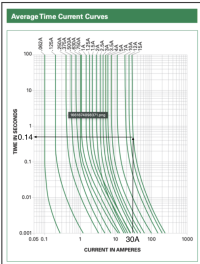

A typical fuse blow time chart looks like this ...

View attachment 170706

The 15A fuse would take more than 100 seconds to blow @30A - it would get very hot - which is why it is necessary to fuse wires correctly, otherwise the fuse holder might melt.

A 40A fuse will survive long enough for the AC load to get going and start drawing less current - the inverter will drop to its continuous output of 350W, which at 10V is ~35A - so the 40A fuse will be fine. The inverter will almost certainly trip and shut-down before the internal fuse blows, but it will allow a peak of 600W for a short time to get equipment with a high startup load going.

An external short circuit of the wiring however will draw as many amps as the battery can provide.

In this situation, the internal 40A fuse is not going to get any current because the wire is shorted before the inverter, here the external 60A fuse will blow pretty quickly because the battery can supply hundreds of amps.

I wouldn't overthink this ... best just follow Sterlings instructions and put a 60A fuse on the supply ... there are thousands of these in service with 12 AWG wiring.