@ebiii

Attached an addendum to Torque - containing the following T6 PIDs

Attached an addendum to Torque - containing the following T6 PIDs

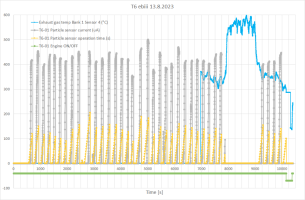

"T6-01 Lambda"

"T6-01 NOx sensor"

"T6-01 Particle sensor current"

"T6-01 Particle sensor operation time"

NOTE: "T6-01 Particle sensor operation time" will be logged only once in 10 seconds - to not unnecessarily slow down logging. However, the others are logged at maximum speed to catch all the fine details.

How-to import:

Torque > Main > Settings > Manage extra PIDs/Sensors > Settings (top right) > Import CSV file

How-to setup logging:

Torque > Main > Settings > Data Logging & Upload > Logging preferences/Select what to log > Settings (top right) > Select what to log > Scroll down to find/tick the above.

At this time perhaps add only the two PIDs related to particle sensor - not to slow down the logging too much. Of course can try with all of them - shouldn't be too bad anyways.

NOTE: the logging and the dashboard are separate/independent things - however, having the same data item in both doesn't slow down logging as Torque is quite smart combining the data.