So, I've been getting the all too common P046C fault code along with P2457 (Insufficient EGR Cooling Performance). Neither alone will flag a check engine light but combined they sometimes seem to. To try to figure out what is going on, I ran an EGR Flow test on VCDS using instruction from @mmi on this rather excellent page:

www.t6forum.com

www.t6forum.com

I didn't spot much relating to the EGR funtion but the EGR valve reading itself was interesting. Basically, it didn't appear to be fully closing.

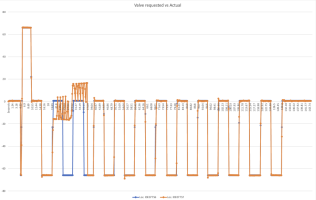

My confidence with VCDS growing, I went on to run the IDE00242-EGR Valve Output Test. My results suggested that the value requested by the ECU didn't match the Actual value returened by the EGR Valve for some values and that, occasionally, it appeared to become 'stuck'. Problem is that I don't have any reference for what a 'healthy' EGR Valve does during this test.

Below is the sequence needed to run the IDE00242 test. It's one of the easier checks to run. If you have a VCDS system yourself (and a spare 20 minutes) I'd be really interested to see your results.

Results:

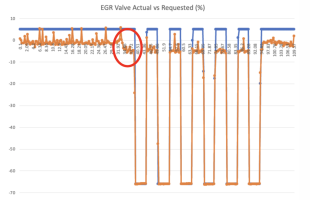

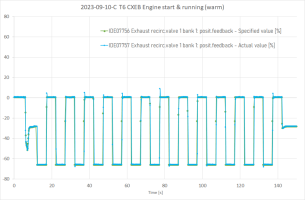

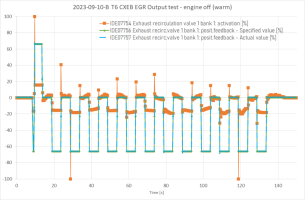

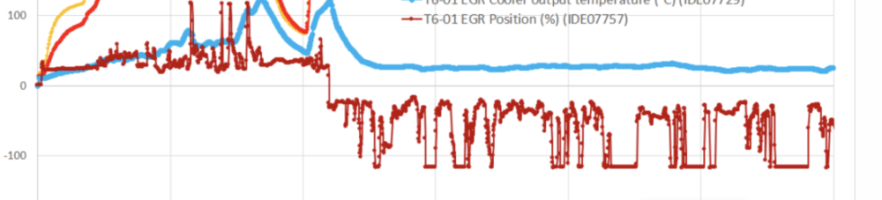

Results from my own van ended uplooking like this (once plotted in excell). Orange is Actual Valve position, Blue is requested.

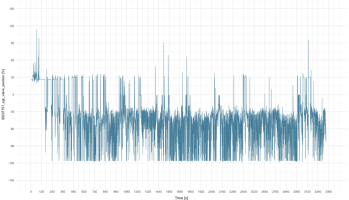

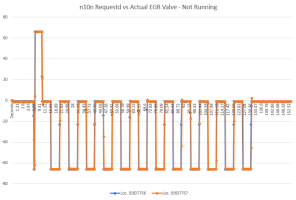

Engine not Running.

The first test showed an initial period where the Actual failed to match the Requested but it sorted itself out mid test.

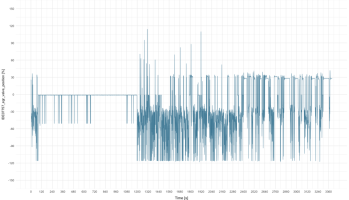

The second and third tests showed reasonable matching between Requested and Actual but with a bit of 'noise' on the actual value.

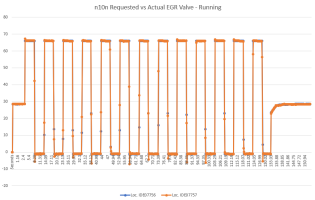

Engine Running:

The fourth test was run with the engine running and the result matched that from the EGR flow test with the valve failing to hit the +5% Requested value.

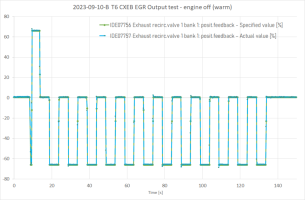

Engine Switched Back Off:

The fifth and sixth tests were then run with the engine switched off again and both showed significant difference between Requested and Actual.

Observations on my own data:

To my mind, it looks like my EGR valve is simply clogged up and the actuator is no longer working as it should. This would certainly explain the P046C 'implausible signal' fault description. Only problem is that I have no data to compare against. Like I say, if anyone could take a look at this test themselves and post data, I'd be very grateful.

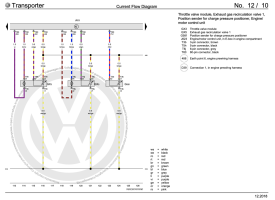

[T6_measured] 01-Engine - Built-in test for EGR

T6.1 DNAA engine The test runs differently than on T6 CXxx engines - less cycles. Instructions of post #1 still apply.

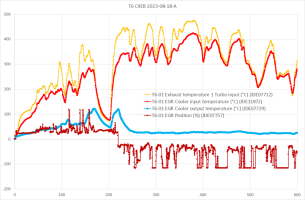

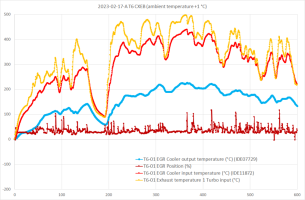

I didn't spot much relating to the EGR funtion but the EGR valve reading itself was interesting. Basically, it didn't appear to be fully closing.

My confidence with VCDS growing, I went on to run the IDE00242-EGR Valve Output Test. My results suggested that the value requested by the ECU didn't match the Actual value returened by the EGR Valve for some values and that, occasionally, it appeared to become 'stuck'. Problem is that I don't have any reference for what a 'healthy' EGR Valve does during this test.

Below is the sequence needed to run the IDE00242 test. It's one of the easier checks to run. If you have a VCDS system yourself (and a spare 20 minutes) I'd be really interested to see your results.

How to:

General conditions

- Proceed as below - Test can be run with the engine running or switched off (ignition on). If you can do both, all the better.

- == Unfortunately can't proceed if DPF regeneration is in progress ==

(1) Create engine blockmap data file

VCDS > Applications > Controller Channel Map >

-

- Tick the boxes as above and click Go

- VCDS flashes screen for approx. two minutes. When finished click Done, Go Back

(2) Run engine's built-in EGR Valve test

- VCDS > Select > Engine > Output Tests

- In the drop down menu, select IDE00242

- Select - Show Measuring Data

- From the list of measurements (tickbox list), select the tickbox for IDE07756 and IDE07757 - These ar the Requested, and Actual EGR Valve values

- Click Log , enter file name

- Click Start (VERY IMPORTANT STEP!!)

- Below IDE00242 (from pull-down menu if not shown), click Start

- Software will now move the EGR valve through a range of values and measure both the Requested and Actual Valve positions (% of open)

- During the test the main window will simply show "Running" but the live measurement data will be dispayed in the measurements window.

- The test take a couple of minutes to run and ends in a Timeout (displayed in main window)

- When finished make a note of the message and let logging run for another 15 seconds

- Stop (the data logging)

- Done, close

- Back out from Basic Settings, Close controller, etc. exit VCDS

- Switch off the engine (if running) etc.

(3) Please post the logs (2 files)

- The log files (2 of them) are in folder C:\Ross-Tech\VCDS\Logs\...

- The file Blockmap-01...CSV is a package of approx 1500 engine parameters - for further and possibly future evaluation of the test (e.g blockage vs. mileage vs. DPF ash accumulation)

- Besides the above the collecting the above at (1) lets engine and exhaust temperatures stabilise so can be compared with others recorded similarly

- The actual log file LOG-01-.....CSV (or named by you) contains timestamped measured values.

Results:

Results from my own van ended uplooking like this (once plotted in excell). Orange is Actual Valve position, Blue is requested.

Engine not Running.

The first test showed an initial period where the Actual failed to match the Requested but it sorted itself out mid test.

The second and third tests showed reasonable matching between Requested and Actual but with a bit of 'noise' on the actual value.

Engine Running:

The fourth test was run with the engine running and the result matched that from the EGR flow test with the valve failing to hit the +5% Requested value.

Engine Switched Back Off:

The fifth and sixth tests were then run with the engine switched off again and both showed significant difference between Requested and Actual.

Observations on my own data:

- The 'at rest' position' of the valve is not Zero. For tests #1, #2, #3, #5 and #6 where the engine was not running, the initial value from the EGR valve is about -10% so slightly open.

- In the one test I ran where the engine was running, the valve never manages to completely close. I have also noticed (through experimentation) that the higher the engine RPM the wider open the valve becomes during the test. In the graph below, for example, I highlight the point in the test where engine RPM changes from 800rpm to 1400rpm. The Requested valve postion does not change but the Actual position opens from around -1% to around -5%

- Most obviously, my EGR valve does not track Requested position particularly well, especially close to 0% and after a large negative to positive swing.

- After running the test a couple of times I captured results #2 and #3 which look relatively clean. I wonder if I'd simply freed up the valve?

- After then running the engine for a while (during test #4), the valve reverted to it's previous (bad) behaviour in tests #5 and #6.

To my mind, it looks like my EGR valve is simply clogged up and the actuator is no longer working as it should. This would certainly explain the P046C 'implausible signal' fault description. Only problem is that I have no data to compare against. Like I say, if anyone could take a look at this test themselves and post data, I'd be very grateful.

Last edited:

. Coincidence?

. Coincidence?