Brake Pad & Disc change - How I Done It -

After a recent trip to the Dealer for Service and Cambelt job, ( we had the dealers do it as we are in a 2yrs extended warranty ) : Cambelt + Water Pump Replacement - Official guidance

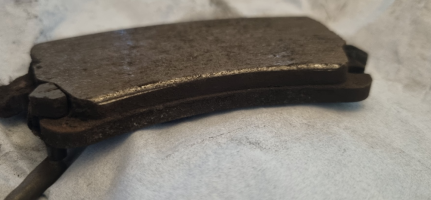

At the time, they advised that the rear pads were 90% worn.

which as we all know is an easy money spinner for them, I'm sure every time I've walked into the dealers they taken one look am me and the van and said "Pads & discs all round -Sir? " without even checking.

anyway we know there game, so i politely declined their offer to do the Pads & Discs at the time and carried on like normal.

in the back of my mind i knew that the front and rear brakes have wear sensors of them, and that these come on when the pads are down to 80/90% - and i hadn't seen any warning yet.

so imagine my surprise when almost two weeks to the day, . . . . . this happened.

that message is triggered form one of the brake pad sensors, there is one on each axel. - its assumed that both side are changed at the same time so they save money and weight by just instaklling two sensors and not four.

OK no big deal, they are obviously due to be changed. were at 52k miles,

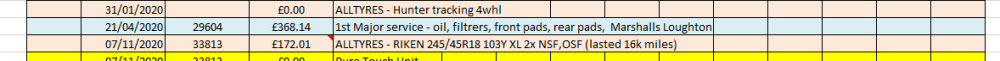

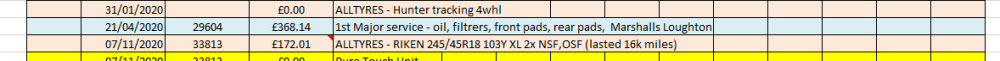

and i can see from my records that the pads were changed all-round at 29k miles.

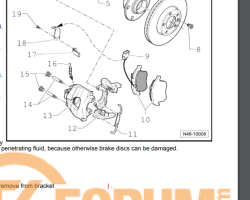

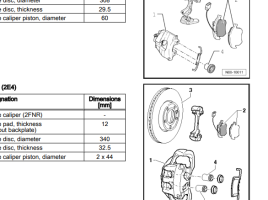

looking over here we can see what's required: Service Parts List - What Goes Where -

++++++++++++++++++++++++++++++++++++++++++++++

Brakes:

Pads:

308mm F Pagid Brake Pad (Front Axle) Product Code: 101441298

340mm F Pagid Pagid Brake Pad (Front Axle)Product Code: 101441868

340mm F Brembo Brembo Brake Pad (Front)Product Code: 10144186A

294mm R Pagid Brake Pad (Rear Axle) Product Code: 101441318

294mm R Brembo Brembo Brake Pad (Rear)Product Code: 10144131A

Discs:

Smaller 308mm Front: Pagid Brake Disc (Front Axle)Product Code: 104441288

larger 340mm front; Pagid Brake Disc (Front Axle)Product Code: 104442118

larger 340mm front Brembo Brembo Brake Disc (Front)Product Code: 10444211A

standard 294mm rears: Pagid Brake Disc (Rear Axle)Product Code: 104441368

standard 294mm rears Brembo Brembo Brake Disc (Rear)Product Code: 10444136A

++++++++++++++++++++++++++++++++++++++++++++++

I run a T32 204 DSG and as such have the Larger 340mm front brakes,

that means i need the :

larger 340mm front; Pagid Brake Disc (Front Axle)Product Code: 104442118

340mm F Pagid Pagid Brake Pad (Front Axle)Product Code: 101441868

standard 294mm rears: Pagid Brake Disc (Rear Axle)Product Code: 104441368

294mm R Pagid Brake Pad (Rear Axle) Product Code: 101441318

++++++++++++++++++++++++++++++++++++++++++++++

Now about a year ago, well, two by now . . . i made use of the BLACK FRIDAY sale and procured a full set of BREMBO pads and discs.

I've had them in the garage ever since . . . . . . 4x discs and a full set of pads.

larger 340mm front Brembo Brembo Brake Disc (Front)Product Code: 10444211A

340mm F Brembo Brembo Brake Pad (Front)Product Code: 10144186A

standard 294mm rears Brembo Brembo Brake Disc (Rear)Product Code: 10444136A

294mm R Brembo Brembo Brake Pad (Rear)Product Code: 10144131A

.

+++++++++++++++++++++++++++++++++

iv already got all the tools to do the job . . so lets that a quick look. . . .

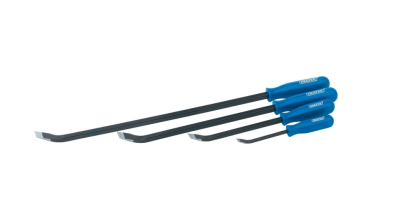

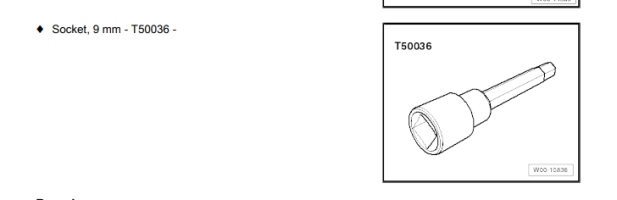

Trolley Jack and axle stands are standard, but there are a few extra bits you need.

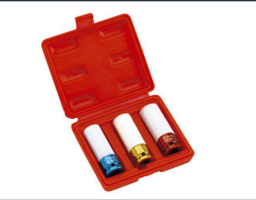

you will need a brake calliper wind back tool, i have the kit form as i do other pad jobs.

+++

Brake cleaner is a must . . .

+++++

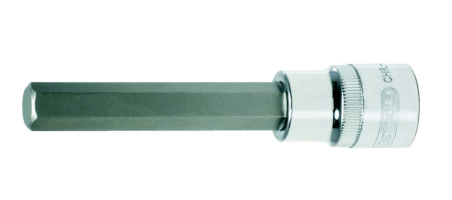

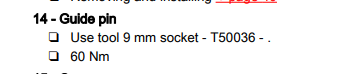

there is the 9mm long bit for the slider guide pin. . . . but i check that fully after.

+++++

Then some standard garage hand tools.

++++++

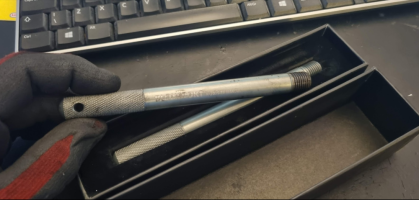

I decided to try this new little ProSlip Grease kit highlighted by a fellow T6F member . .

.

ill be doing the job soon . .

so starting this thread now.

.

After a recent trip to the Dealer for Service and Cambelt job, ( we had the dealers do it as we are in a 2yrs extended warranty ) : Cambelt + Water Pump Replacement - Official guidance

At the time, they advised that the rear pads were 90% worn.

which as we all know is an easy money spinner for them, I'm sure every time I've walked into the dealers they taken one look am me and the van and said "Pads & discs all round -Sir? " without even checking.

anyway we know there game, so i politely declined their offer to do the Pads & Discs at the time and carried on like normal.

in the back of my mind i knew that the front and rear brakes have wear sensors of them, and that these come on when the pads are down to 80/90% - and i hadn't seen any warning yet.

so imagine my surprise when almost two weeks to the day, . . . . . this happened.

that message is triggered form one of the brake pad sensors, there is one on each axel. - its assumed that both side are changed at the same time so they save money and weight by just instaklling two sensors and not four.

OK no big deal, they are obviously due to be changed. were at 52k miles,

and i can see from my records that the pads were changed all-round at 29k miles.

looking over here we can see what's required: Service Parts List - What Goes Where -

++++++++++++++++++++++++++++++++++++++++++++++

Brakes:

Pads:

308mm F Pagid Brake Pad (Front Axle) Product Code: 101441298

340mm F Pagid Pagid Brake Pad (Front Axle)Product Code: 101441868

340mm F Brembo Brembo Brake Pad (Front)Product Code: 10144186A

294mm R Pagid Brake Pad (Rear Axle) Product Code: 101441318

294mm R Brembo Brembo Brake Pad (Rear)Product Code: 10144131A

Discs:

Smaller 308mm Front: Pagid Brake Disc (Front Axle)Product Code: 104441288

larger 340mm front; Pagid Brake Disc (Front Axle)Product Code: 104442118

larger 340mm front Brembo Brembo Brake Disc (Front)Product Code: 10444211A

standard 294mm rears: Pagid Brake Disc (Rear Axle)Product Code: 104441368

standard 294mm rears Brembo Brembo Brake Disc (Rear)Product Code: 10444136A

++++++++++++++++++++++++++++++++++++++++++++++

I run a T32 204 DSG and as such have the Larger 340mm front brakes,

that means i need the :

larger 340mm front; Pagid Brake Disc (Front Axle)Product Code: 104442118

340mm F Pagid Pagid Brake Pad (Front Axle)Product Code: 101441868

standard 294mm rears: Pagid Brake Disc (Rear Axle)Product Code: 104441368

294mm R Pagid Brake Pad (Rear Axle) Product Code: 101441318

++++++++++++++++++++++++++++++++++++++++++++++

Now about a year ago, well, two by now . . . i made use of the BLACK FRIDAY sale and procured a full set of BREMBO pads and discs.

I've had them in the garage ever since . . . . . . 4x discs and a full set of pads.

larger 340mm front Brembo Brembo Brake Disc (Front)Product Code: 10444211A

340mm F Brembo Brembo Brake Pad (Front)Product Code: 10144186A

standard 294mm rears Brembo Brembo Brake Disc (Rear)Product Code: 10444136A

294mm R Brembo Brembo Brake Pad (Rear)Product Code: 10144131A

.

+++++++++++++++++++++++++++++++++

iv already got all the tools to do the job . . so lets that a quick look. . . .

Trolley Jack and axle stands are standard, but there are a few extra bits you need.

you will need a brake calliper wind back tool, i have the kit form as i do other pad jobs.

+++

Brake cleaner is a must . . .

+++++

there is the 9mm long bit for the slider guide pin. . . . but i check that fully after.

+++++

Then some standard garage hand tools.

++++++

I decided to try this new little ProSlip Grease kit highlighted by a fellow T6F member . .

.

ill be doing the job soon . .

so starting this thread now.

.