I did my fronts a couple of weeks ago. Make sure you get all your ducks in a row before you start.

I got a new torque wrench, a loooong breaker bar and a 9mm long Allen key socket and brake cleaner and axle stands.

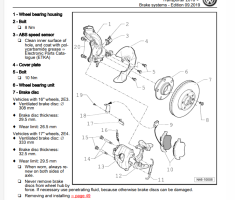

It was straightforward. Jack up, axle stands, wheels off. Spray release agent onto retainer bolt.

Remove retainer clip,which on the big brakes is a bugger, then unbolt caliper carrier bolts. Breaker bar worked a treat here.

Then undo the carrier bolts and remove the caliper carrier.

Remove retainer screw and use a big persuader (lump hammer) to knock the disc off. Clean the hub mating face so it shines lol then wind back the pistons.

I used a wind back tool because I already have one. BUT with twin pistons you need to put a piece of ply or similar across the two pistons otherwise as you wind one in the other comes out. Doh!

Oh yeah, remove brake fluid cap before this stage and put some old rags round in case you push fluid out in the wind back process.

Then new disc, retainer screw and reassemble using ceratec lube (not copper slip) on moving edges and rear of pads (that’s what it stated on my pads). Also lube the slider bolts before you reinsert them.

Then pad into caliper and put caliper on and tighten to correct torque. Then put carrier/pad on and bolt up to correct torque. Then put the retainer clip back on. That is massive fun…..not.

Then clean the caliper and paint it orange and put the wheels back on.

Reservoir cap back on then pump the brake pedal a few times until firm.

Then follow pad manufacturer instructions to bed them in.

If I’ve missed anything I apologise but that’s just from memory.

It’s pretty straightforward.

View attachment 162532

www.t6forum.com

www.t6forum.com