It is surprising the amount of solder that will wick into a crimped joint, it shows how the corrosion can start.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Battery cable crimping tool recommendation please

- Thread starter YellowHound

- Start date

We solder all joints and crimp battery, accessories terminals etc.

Cheers

Ian

Cheers

Ian

an interesting watch re-soldering lugs

hyro crimp + solder (Marine)

.

hyro crimp + solder (Marine)

.

Last edited:

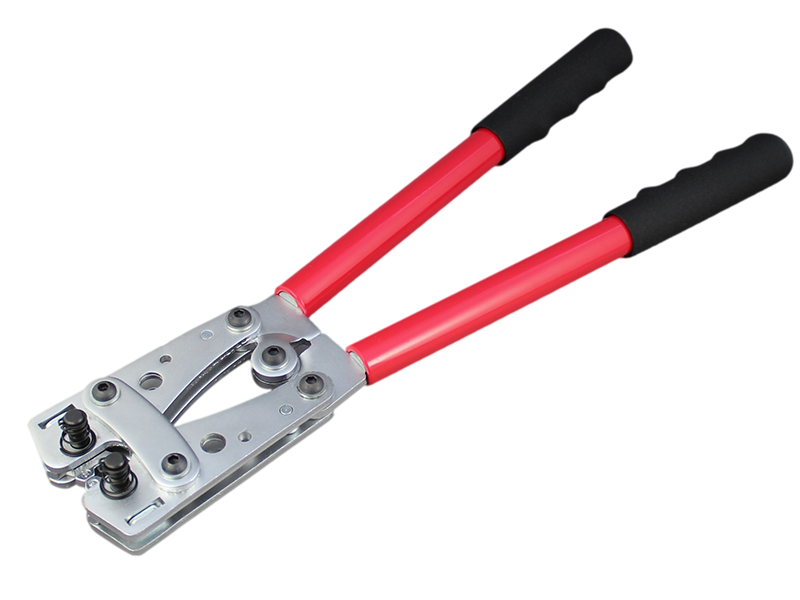

Dellmassive, I suppose you dont happen to have a supplier for this crimper do you...??????next up is this beauty . . . my first port of call and go to large crimper.

it will crimp most large lugs and crimps . . . . if it fits on the gap . . . it will crimp it.

I've have some tough crimps before . . . and even with 15stone leaning down on it its not broke.

its big at 13 inches long.

this is the most used crimper for large cables.

i cant remember where i got it from now . . . but been using it a couple of years now.

View attachment 105191View attachment 105192

next up . .

sure . . . .Dellmassive, I suppose you dont happen to have a supplier for this crimper do you...??????

basically same thing . . .

SWA RP625 Crimping Tool Ratchet for Uninsulated Terminals 6 mm-25 mm : Amazon.co.uk: DIY & Tools

SWA RP625 Crimping Tool Ratchet for Uninsulated Terminals 6 mm-25 mm : Amazon.co.uk: DIY & Tools

amzn.to

Thanks matey.... I did put the letters and number on the smaller pic of the head into google but came up with nothing... and also looked through the images on google...saw loads of various kinds but not the exact ones... but if this is the same thing... then I will get one ordered... cheers.... Boysan..sure . . . .

basically same thing . . .

SWA RP625 Crimping Tool Ratchet for Uninsulated Terminals 6 mm-25 mm : Amazon.co.uk: DIY & Tools

SWA RP625 Crimping Tool Ratchet for Uninsulated Terminals 6 mm-25 mm : Amazon.co.uk: DIY & Toolsamzn.to

View attachment 125201

View attachment 125202

Couple of points on crimping ...

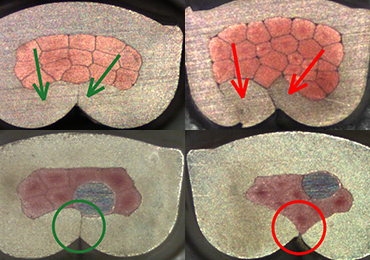

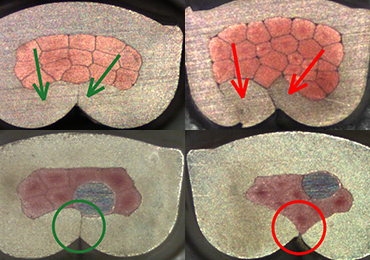

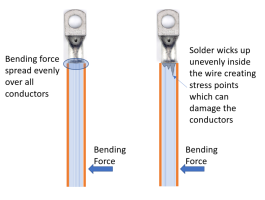

If crimped properly there is no space inside the crimp for solder to wick into ... therefore it wicks up inside the wire instead.

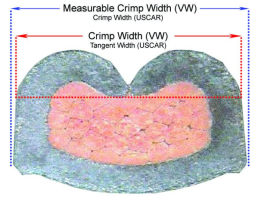

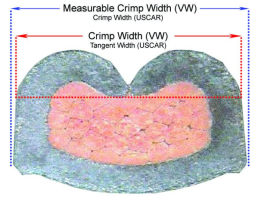

Cross-section of a good crimp looks like this ....

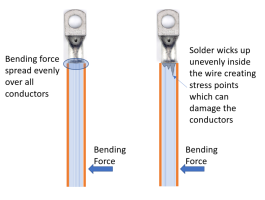

Solder wicking up the wire creates stress points in the conductors and can lead to premature failure.

Soldering before crimping means your conductor no longer has the correct cross sectional area for the crimp, and the compression characteristics of the conductors are changed, so the crimp tool will most probably damage either the connector, the conductors, or both.

Always use the correct connector for the wire size and a good quality crimp tool is all that is required. In the aeronautical industry, and the automotive industry, crimp connections are never soldered.

There is a use-case for soldering when the wire is connected directly to a device, but If it is a removeable connection, it should be crimped.

If crimped properly there is no space inside the crimp for solder to wick into ... therefore it wicks up inside the wire instead.

Cross-section of a good crimp looks like this ....

Solder wicking up the wire creates stress points in the conductors and can lead to premature failure.

Soldering before crimping means your conductor no longer has the correct cross sectional area for the crimp, and the compression characteristics of the conductors are changed, so the crimp tool will most probably damage either the connector, the conductors, or both.

Always use the correct connector for the wire size and a good quality crimp tool is all that is required. In the aeronautical industry, and the automotive industry, crimp connections are never soldered.

There is a use-case for soldering when the wire is connected directly to a device, but If it is a removeable connection, it should be crimped.

If its multi stranded cable it is always recommended that they be hex crimped to give full current flow and stop bad joints.

We had this problem years ago at Peugeot on the high current welders,when federal electric came in they picked up that the cables were indent crimped not hex crimped.

All joints had to de re done.

We had this problem years ago at Peugeot on the high current welders,when federal electric came in they picked up that the cables were indent crimped not hex crimped.

All joints had to de re done.

Glad to hear that - when I did my boat, everything was hex-crimped with hydraulic crimpers, the crimping dies were good quality and the cable connectors were too. The cable was 95mm2. I cut a few test crimps through to see what they looked like inside - the individual conductor strands were squashed into hexagons and there were no air gaps. The hydraulic crimper was pumped until the dies touched. Very happy with the results and the crimped ends would hold my weight ... tested that too. Must have made about 20-30 connections in the battery compartment.If its multi stranded cable it is always recommended that they be hex crimped to give full current flow and stop bad joints.

We had this problem years ago at Peugeot on the high current welders,when federal electric came in they picked up that the cables were indent crimped not hex crimped.

All joints had to de re done.

Are tools for hexagonal crimping a DIY option, or is anything DIY-priced not up to the job?

I have some van work to do which I believe will involve making up some new cables - I'd like them to be of the right quality. I don't mind buying the tools I need (within reason - £££!) as I see them as an investment that will pay me back over time.

But I want to be the right tool, and there is the challenge - buying something that will fit DIY usage (some compromises on quality as it's not something that will see daily frequent pro use) but still up to the job it is designed for.

Any recommendations for hex crimping tools please??

Or is indent crimping where I should be looking?

I have some van work to do which I believe will involve making up some new cables - I'd like them to be of the right quality. I don't mind buying the tools I need (within reason - £££!) as I see them as an investment that will pay me back over time.

But I want to be the right tool, and there is the challenge - buying something that will fit DIY usage (some compromises on quality as it's not something that will see daily frequent pro use) but still up to the job it is designed for.

Any recommendations for hex crimping tools please??

Or is indent crimping where I should be looking?

Some additional info here.

www.t6forum.com

www.t6forum.com

....

Battery cable crimping tool recommendation please

As per the title. Lots of options but the reviews are mixed at best, though anything I buy will not see anything more than light use. Been looking at the hydraulic options, like this ColdShine Hydraulic Crimper Tool Kit Tube Terminals Lugs Battery Cable Wire Crimping Force: Amazon.co.uk...

....

Have the hydraulic hex crimper..... And to be honest I'm not keen on it.

You need the perfect lug for the perfect size die, I've found that as all crimp lugs vary it was very difficult to get a perfect crimp that wouldn't pull off with

stand and pull test..... Or the other thing I was getting was a lug squash where it would sqeeze the lug with two tabs.

that's just my experience with it.

what I found was the most effective for large battery terminals was the sprung loaded hammer smash tool.

that worked great with a beefy club hammer.

the only problem was that is fine to make crimps on the floor.....but not so good if you needed to make a crimp in situ in the van.

You need the perfect lug for the perfect size die, I've found that as all crimp lugs vary it was very difficult to get a perfect crimp that wouldn't pull off with

stand and pull test..... Or the other thing I was getting was a lug squash where it would sqeeze the lug with two tabs.

that's just my experience with it.

what I found was the most effective for large battery terminals was the sprung loaded hammer smash tool.

that worked great with a beefy club hammer.

the only problem was that is fine to make crimps on the floor.....but not so good if you needed to make a crimp in situ in the van.

I think there are simply too many suppliers of cheap tools and parts - and I mean that not just in terms of cost, but also in terms of precision and material quality.Have the hydraulic hex crimper..... And to be honest I'm not keen on it.

You need the perfect lug for the perfect size die, I've found that as all crimp lugs vary it was very difficult to get a perfect crimp that wouldn't pull off with

stand and pull test..... Or the other thing I was getting was a lug squash where it would sqeeze the lug with two tabs.

that's just my experience with it.

what I found was the most effective for large battery terminals was the sprung loaded hammer smash tool.

that worked great with a beefy club hammer.

the only problem was that is fine to make crimps on the floor.....but not so good if you needed to make a crimp in situ in the van.

I don't mean to be dismissive or confrontational, but the hammer smash method is not something I would personally use. One of the most important things about crimping is guaranteeing consistency. I have found a hydraulic crimp tool, a lug supplier, and a cable supplier where everything works well together, and the crimps are of a consistent high quality. With a hammer smash, the repeatability is not guaranteed as it is operator dependent, and there is a danger that the lug or wire can be fractured and weakened by over compression - when this occurs inside the crimp it is invisible - but in the same way as a skilled welder can produce excellent welds - comparable to a robotic welder - I'm sure @Dellmassive can produce excellent crimp results and it looks like the results are checked with an infra-red camera, so damaged lugs/wires will show up as hotspots on a high-current test - and practice makes perfect.

IMO, when it comes to consistency, quality, and repeatability for occasional users then a ratchetted tool, or a hydraulic tool with precision dies, will produce a more consistent and reliable result - buy or hire a quality tool, and buy cable and lugs from a reputable supplier, rather than the cheapest that can be found on E-Bay.

Obviously if the tools, the lugs, or the wires are poor quality then they will produce poor results. There is a good description of the various crimp options in a paper produced by the German tool manufacturer Klauke in the following link:

https://www.klauke.com/Media/Defaul...BRFACH19GB_Klauke Fachwissen_02_2019_I_GB.pdf

I don't know about other forum members, but I've spent a small fortune on my toys (boat and van) so a few hundred euros invested in quality tools is worth it IMO.

I have one of those yellow hydraulic ones (im a sparky) and find it pretty shit, last couple years i have bought a couple manual hex crimpers and find them so much better (and cheaper) no fluid to leak and not much to go wrong, will run out to van and add a pic of the one i am using at the moment

It does 6-50mm crimps so covers most things we need it for, got mine from 12v planet

It does 6-50mm crimps so covers most things we need it for, got mine from 12v planet

This seems to be their current equivalent

Copper Tube Terminal Hexagon Crimping Tool 6 - 50mm²

Heavy duty hexagon crimping tool for copper tube, open ended and butt terminals, cable size 6-50mm². Revolvable dies for different sized terminals.

www.12voltplanet.co.uk

Rather than buy a crimper for near £40 for what could be four uses/crimps, can we hire them?

Possible.Rather than buy a crimper for near £40 for what could be four uses/crimps, can we hire them?

It would probably cost £16 for shipping both ways.

Having recently spent a flippin' fortune on terminal crimpers, terminals and Anderson connectors of mannnnnny sizes I have found these to be my favourites. I also have MS which makes my fine motor skills unreliable - usually I twitch at exactly the wrong moment and manage to fling what I'm working on which is a real issue with tiny crimps (they vanish) or when putting a lot of pressure on a tool that twists or spins smashing stuff around me (favourite mug hit the gravel at the weekend).

Anyway, the tools I found most suitable are:

HS-16 - currently £16 on Amazon

15A / 30A /45A Anderson Power Pole clone tool - currently £35 including a selection of clone power pole crimps

My new favourite tool is this beast, 10-120mm2 dieless crimp tool currently £70 on eBay This is the one that I twitched whilst using and my faithful coffee mug took an unscheduled flight with an unsurvivable landing. Its really forgiving - mismatch between lugs and cable sizes? Just keep turning the screw and squishing the crimp until you definitely can't pull the cable out - using flared crimps that are too big for your heatshrink? Squish the flare out of it. Simples.

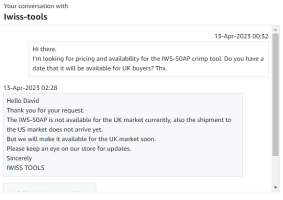

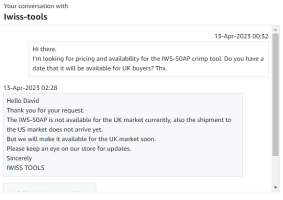

I've tried the hex tools etc but I don't have the controlled strength to get satisfactory crimps so I've gone around them all again and re-squished with the beast. I've also used it for Anderson SB350 terminals which were really surprisingly easy to squish. I'm still looking for a perfect tool for Anderson SB50 / PP75 terminals (Iwiss have developed one but its not generally available yet IWS-50AP) the genuine Anderson tool is £250 which is really way more than I want to spend.

The tool I regret buying is:

10 -125mm2 hydraulic crimper - currently £35 on Amazon.

Its huge, heavy and as others have said, needs crimps that match the dies. If you want to try it (or buy it off me for £20), PM me and come and get it from Sidmouth, EX10 0BQ in Devon. One careful owner, 6 months old, barely used

I've tried soldering some cables but 95mm2 cable does not lend itself well to my soldering iron (too wimpy) or blowtorch (fiery destruction).

D

Anyway, the tools I found most suitable are:

HS-16 - currently £16 on Amazon

15A / 30A /45A Anderson Power Pole clone tool - currently £35 including a selection of clone power pole crimps

My new favourite tool is this beast, 10-120mm2 dieless crimp tool currently £70 on eBay This is the one that I twitched whilst using and my faithful coffee mug took an unscheduled flight with an unsurvivable landing. Its really forgiving - mismatch between lugs and cable sizes? Just keep turning the screw and squishing the crimp until you definitely can't pull the cable out - using flared crimps that are too big for your heatshrink? Squish the flare out of it. Simples.

I've tried the hex tools etc but I don't have the controlled strength to get satisfactory crimps so I've gone around them all again and re-squished with the beast. I've also used it for Anderson SB350 terminals which were really surprisingly easy to squish. I'm still looking for a perfect tool for Anderson SB50 / PP75 terminals (Iwiss have developed one but its not generally available yet IWS-50AP) the genuine Anderson tool is £250 which is really way more than I want to spend.

The tool I regret buying is:

10 -125mm2 hydraulic crimper - currently £35 on Amazon.

Its huge, heavy and as others have said, needs crimps that match the dies. If you want to try it (or buy it off me for £20), PM me and come and get it from Sidmouth, EX10 0BQ in Devon. One careful owner, 6 months old, barely used

I've tried soldering some cables but 95mm2 cable does not lend itself well to my soldering iron (too wimpy) or blowtorch (fiery destruction).

D

Last edited:

I'm going to help others locally by saying, if you want to borrow my crimper you are welcome! I live in SW Fife, and it would save you buying your own one for it to be used very infrequently and sat in your tool box mostly!

Last edited:

Similar threads

- Replies

- 8

- Views

- 1K

- Replies

- 7

- Views

- 2K

- Replies

- 145

- Views

- 18K