You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

T6.1 4Motion Camper-Conversion to carry dogs

- Thread starter dejansuc

- Start date

Won't it be pitch black in the dog crate when the tailgate is shut?

He is a rescue dog, he is used to the dark

Anyway, when the dog is not working, it is the best for him to rest in quiet place.

I will install cooling fans on one side of the crate to move some cold air from the cabin to the crate.

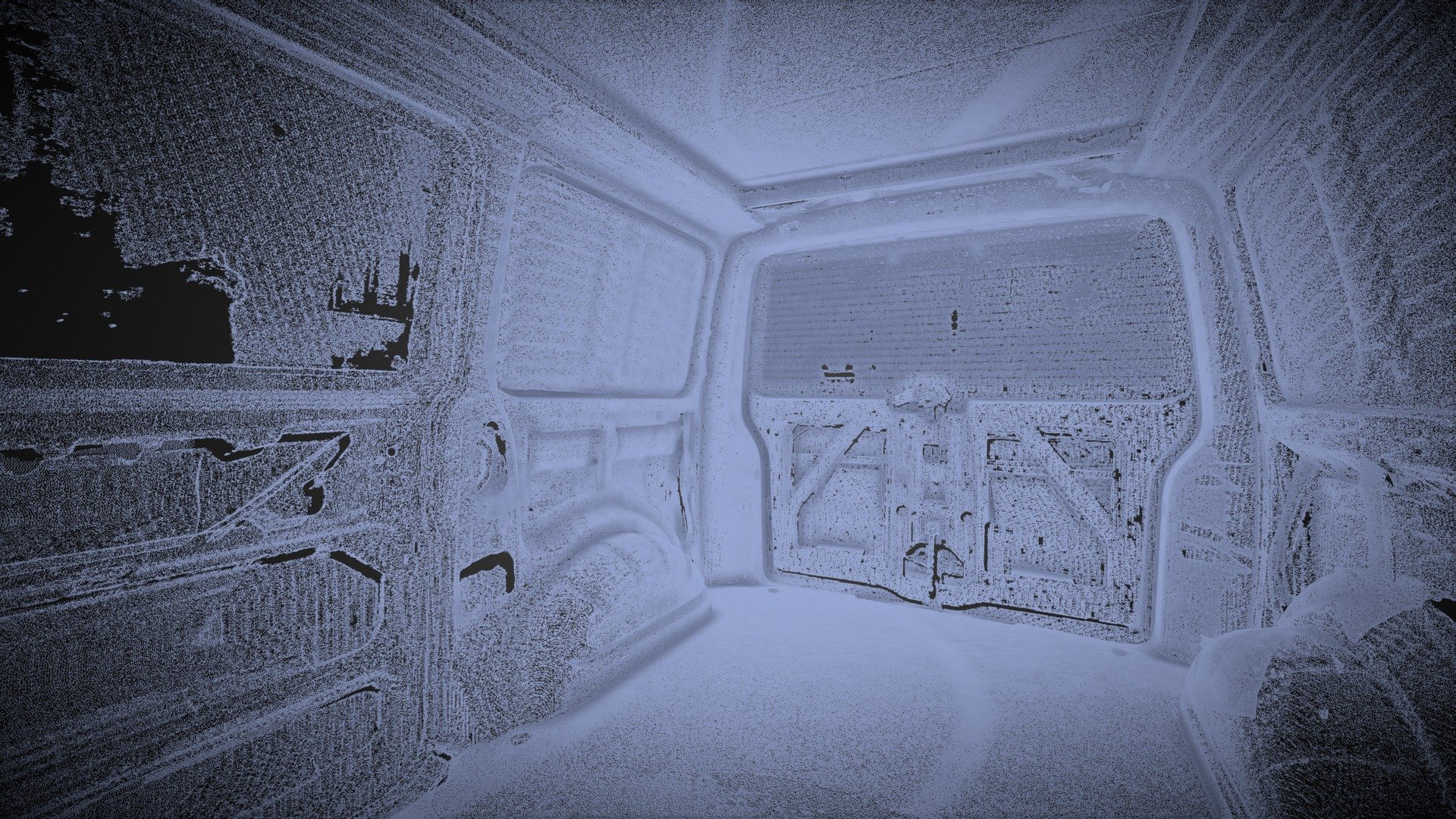

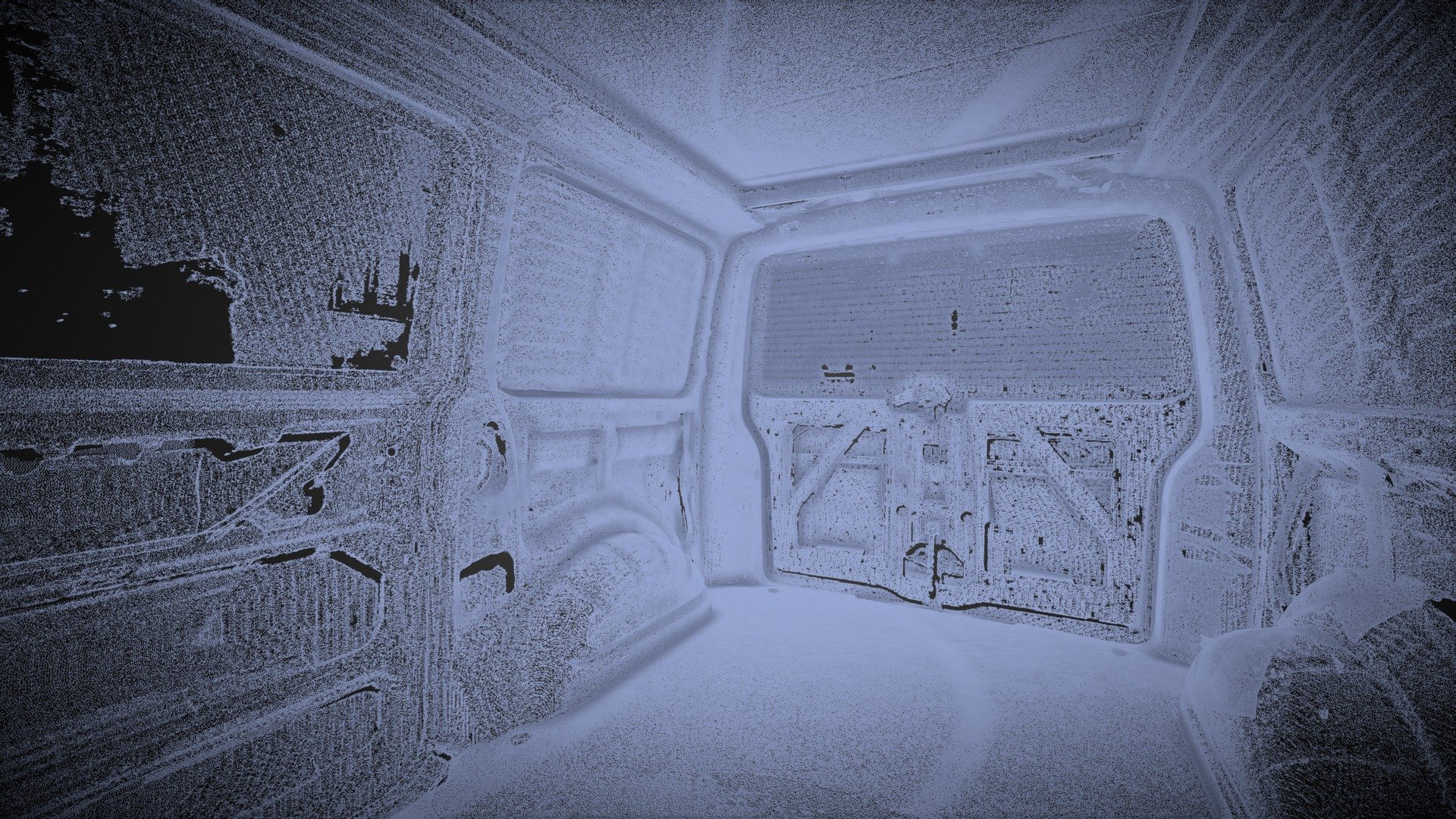

I scanned the interior of T6.1 furgon with Leica RTC360 laser scanner from two positions, interior and under the tailgate. Scans are 100% aligned and merged together. Original pointcloud is 6Gb with more than 220M points!!

I filtered and deleted some "noise" and reduced the model to 13M points (~200Mb) in order to upload it to Sketchfab.

sketchfab.com

If you are able, please consider making a small donation. PPL link is under my profile page on sketchfab.

sketchfab.com

If you are able, please consider making a small donation. PPL link is under my profile page on sketchfab.

I filtered and deleted some "noise" and reduced the model to 13M points (~200Mb) in order to upload it to Sketchfab.

VW T6.1 furgon pointcloud [reduced] - Download Free 3D model by suc (@dejans)

scanned with Leica RTC360 3D Laser Scanner 2 aligned scans (interior and under the open tailgate) reduced merged point clouds from 220M (original) to 13M - VW T6.1 furgon pointcloud [reduced] - Download Free 3D model by suc (@dejans)

Last edited:

Would It be possible to share the basis of this in a Sketchup compatible format ?I'm thinking about building a frame for cabinets, dog kennel and bench from extruded aluminium profiles. 30x30mm profiles are lightweight and strong.

extruded alu frame / plywood furniture

View attachment 75258View attachment 75259

View attachment 75260View attachment 75261

View attachment 75262View attachment 75263

File is in Rhino format. You can download a trial version from Rhino - Downloads and export layers to diferent formats.Would It be possible to share the basis of this in a Sketchup compatible format ?Just ordered my new T6.1 and also want to make an aluminium extrusion build out. Thanks a lot

t6-110t6forum.zip

.LAS file is a pointcloud. This is not a 3D model.... you have to open it with Recap/Blender/Metashape and start to build polygons on pointcloud base if you want a 3D polygonal models (IGES, STEP...)Hello,

Is it possible to convert the .LAS to a .STEP or .IGES?

Thanks a lot.

Thank you for the answer. How did you manage to machine the panels without 3D model?.LAS file is a pointcloud. This is not a 3D model.... you have to open it with Recap/Blender/Metashape and start to build polygons on pointcloud base if you want a 3D polygonal models (IGES, STEP...)

No need to build a polygonal 3D model for CNC cut. I just extracted some curves of van interier directly from the pointcloud (image01), measured the distances between the alu profiles (image02) and drew/closed the curves in Rhino3D.Thank you for the answer. How did you manage to machine the panels without 3D model?

You basically only need curves for CNC cut.

Here you go. t6-110t6forum-step.zipCan you convert the Rhino model to Step, please. Solidworks interprets the Rhinofile as a 6m wide lorry and the shape of the floor does not match your photographsView attachment 136550

I just want to point out that I used and made Rhino file only as a sketch, so dimension are not accurate. That's why I scanned the interior of T6.1 furgon with Leica RTC360 laser scanner. Use attached PointCloud (.las file) if you want better accuracy (0.5mm)!

I drilled soem holes and inserted bolts with nuts.... M6 if I remember..So my van is finally coming in march. Can you enlighten me how you attached the alu profil to the wall? From my understanding something needs to be done to get it square as the van is tilted at this point ?

Be careful, because the window is not in level with the floor!

Firstly mount the horizonal alu profile (below the windows) and leave bolts loose. When you mount the vertical alu profiles (from floor profiles to horizonal profile below the window) it will turn horizontal (loose) profile 90' exactly. Now you can tighten the screws. No need to shim.

Similar threads

- Replies

- 22

- Views

- 1K

- Replies

- 4

- Views

- 793

- Replies

- 13

- Views

- 727