@Loz has made a few:Has anyone found such a slotted rubber puck that can take the weight? I change wheels twice a year (summer/winter) and have not found a puck yet that has not split by the time I have changed 4 wheels.

Can be many things, softwood, a Hockey Puck, custom moulded Polymorph are all the things I have used in the past.

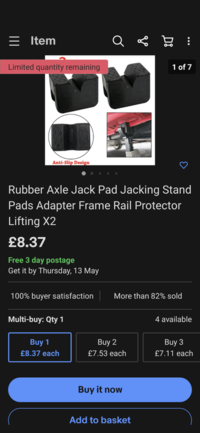

Here are a couple of my custom ones.

View attachment 20315 View attachment 20316View attachment 20317