a few bits here . . .

Commissioning of air conditioning system after filling refrigerant circuit

– Switch on ignition.

– Set fresh air blower speed to at least level 3 on operating and

display unit.

– Set temperature to max. cold on operating and display unit.

– Set air distribution to torso on operating and display unit.

– Start engine with air conditioner compressor switched off (ver‐

sion with magnetic clutch).

– Following idling speed stabilisation, switch on air conditioning

system using A/C button on operating and display unit.

– Allow engine to run for at least 2 minutes at less than 1500 rpm

with air conditioning system switched on. |

Risk of damage to the air conditioner compressor or air condi‐

tioner service station.

Opening the valves with the air conditioning system switched

on can cause a short circuit between the high pressure and low

pressure side.

– Never open valves on the high pressure or low pressure side

with the air conditioning system switched on.

– If necessary, check pressures in refrigerant circuit using air

conditioner service station .

– Switch off engine.

– Turn out handwheel on quick-release coupling adapter.

– Detach the charging hose from the refrigerant circuit.

– Screw protective caps back on.

**************************************

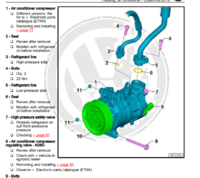

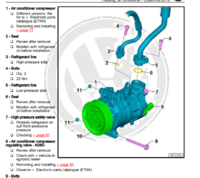

Air conditioner compressor

.

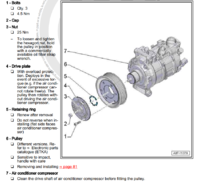

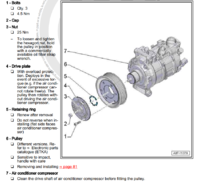

| Removing |

| Note |

| Instead of the poly V-belts being removed completely, they are |

just removed from the air conditioner compressor pulley.

– Relieve tension from poly V-belt ⇒ Rep. gr. 13 ; Cylinder block

on pulley side; Removing and installing poly V-belt .

– Remove poly V-belt from air conditioner compressor pulley.

Vehicles with R134a refrigerant

– Drain refrigerant circuit ⇒ Air conditioning system with R134a

refrigerant; Rep. gr. 00 ; Working with air conditioner service

station .

Vehicles with R1234yf refrigerant

– Drain refrigerant circuit ⇒ Air conditioning systems with re‐

frigerant R1234yf - general information; Rep. gr. 87 ; Working

with air conditioner service station; Draining refrigerant circuit .

Continued for all vehicles

| CAUTION |

Risk of freezing injury caused by escaping pressurised refrig‐

There is a risk of injury to the skin and parts of the body due to

freezing.

– Wear protective gloves.

– Wear protective goggles.

– Extract refrigerant and open the refrigerant circuit immedi‐

ately afterwards.

– If more than 10 minutes have passed since the refrigerant

was extracted, repeat the extraction process before opening

the refrigerant circuit. Pressure could build up in the refrig‐

erant circuit from continued evaporation. |

erant.

– For any further work, immediately seal open lines and con‐

nections with clean plugs from engine bung set - VAS 6122- .

.

****

| Installing |

| Install in reverse order of removal, observing the following: |

Procedure for installing new air conditioner compressor

– Determine refrigerant oil volume in removed air conditioner

compressor by draining oil into measuring beaker. |

| Note |

Collect refrigerant oil from the new air conditioner compressor in

a suitable container for reuse.

– Drain refrigerant oil from new air conditioner compressor.

– Fill exact same amount of refrigerant oil into the new, emptied

air conditioner compressor as that determined in the removed

air conditioner compressor.

.....

Procedure for installing new air conditioner compressor

– Use ⇒ Vehicle diagnostic tester to run-in air conditioner com‐

pressor.

Note

♦ The LED of the A/C button flashes while the air conditioner

compressor runs-in.

♦ The end of air conditioner compressor run-in is indicated by

the LED of the A/C button going out or staying lit.

Continued for all vehicles

– Check operation of heater and air conditioning system.