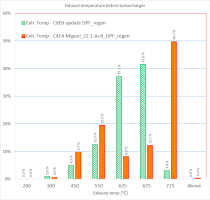

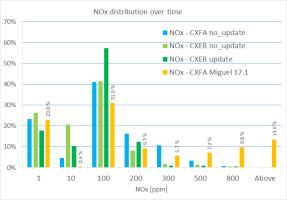

Yes, partially true. The old software had a distictive feature during DPF regen which produced fairly high NOx levels. I'm putting together a package with three different engine softwares: 1) yours 2) the mentioned CXEB before the update 3) the mentioned CXEB after the update.So... with that context, that data is from a van where this system was not optimised yet (old software)

Not necessarily - interestingly it seems that the engine doesn't even try to compensate high NOx with more AdBlue. To me it looks like the AdBlue injection is generally more based on "predicted" emissions based on fuel injected, air flow, exhaust temperatures, etc. The feedback only via NOx sensor would be always late, I think. Also it takes quite a while for the NOx sensors to reach operating temperature and engine till then must run by "default" values.This really bothers me, that means adblue system is trying to compensate this high amount of NOx particulates and the fault comes up when adblue is in the limit and can not compensate enough... is this assumption correct?

Not sure about stuck EGR - we were recording actual position - the engine would throw a fault if the "commanded" and "actual" would deviate. I'm more inclined to what's in the remap about EGR.This may be the reason why the sensor detect such amount of nox... if the is not opened enough ( due to too much dirty?) there isnt enough recirculation and NOx needs work harder to compensate even though some times goes beyond the limit.

I think this relates to the above - the combustion temperatures.I dont really know how to interpret this value... id there is too much oxygen in the exhaust gases.. does it mean the combustion is not efficient? By this statement, do you think the EGR may be faulty?

Again, it looks like the EGR is doing exactly what the ECU asks for - of course blocked EGR cooler would cause lambda to go up, but then I would expect to see engine trying to compensate that by squeezing EGR more (which we do not see happening now).

The mileage 195.000 km's suggests the EGR cooler has already been replaced at least once? Do you know the history of your van, when it was remapped, etc.?Also, the van has (after the second light) gone through after a descarbonization proccess which is supposed to clean EGR, turbo, DPF etc.

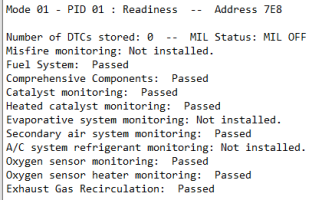

Meanwhile, you could check what the engine thinks about emission readiness.

It would be in

VCDS > OBD-II functions > Mode 1-01 Readiness > Address 7E8

and

VCDS > OBD-II functions > Mode 9 Vehicle Info

Because the fault codes were cleared quite recently some of the tests running in the background might not be complete yet?

)

)