After reading loads of amazingly informative threads on this forum, I thought I'd start my own thread. (Largely inspired by @Dellmassive 's really blooming useful and informative "How I done It!" thread.)

Basically, I haven't "done it" and simply intend on "doing it"!

I thought it would be good to have a thread on this forum that can be used as a sounding board before I get things totally wrong!!

The reason for this post is that I have a new vehicle on order which I am going to be using as a "Demonstrator" for some kit that my company sells and installs in the marine leisure industry. It turns out that there are loads of differences between boats and vans!.........Smart alternators, 12 volts (Who thought that was better than 24V!), massive conducting body shell, etc.

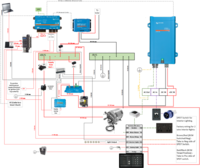

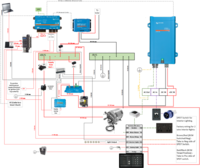

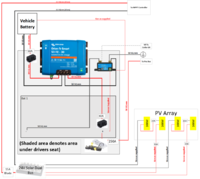

I thought I'd kick off my thread with a diagram of how i intend on "Doing it”.

Not too sure why I’m questioning this but I’m not sure about the use of a smart shunt when all the negs are running off to the chassis. I have simply taken the shunt to ground and then also grounded the main neg bus to the chassis and I am confident that this is right, but boats don't have a convenient metal body to use as a gigantic bus bar. Can I check that this is the correct thing to do with one of the "Gurus" on here?

Notes that help explain oddities in my schematic:

A. The water heater is to only run on twelve volts (from the leisure battery) when the following criteria is met:

1. Engine is running and leisure battery is charging through DC DC charger.

2. More than 10% of water in FW tank.

3. Leisure battery is more than 50% charged (Or whatever other percentage is chosen after install.)

Or

Solar input exceeds 20A and battery charge is greater than 70% (or whatever other percentage is chosen after install.)

B. There is an isolated regulated 12v supply for sensitive electronics and also to stop regular faffing around with fuse of the Wallas hob when the voltage falls slightly under 12.6volts. (Couldn’t Wallas fit a voltage stabiliser theirselves to improve the reliability of their otherwise excellent kit?)

The rest seems pretty self explanatory, but if anyone has any better ideas or any suggested changes I'd love to know?

I would rather know that I have a poor design now than after installing all of the kit, so hoping I may get some constructive feedback:

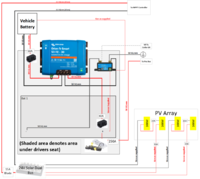

The front end of the installation, including 400W of solar and DC-DC Charger and Lithium battery under the drivers seat. Note the Smart Shunt being taken straight to the body of the vehicle. This is the bit that is alien to me!

Basically, I haven't "done it" and simply intend on "doing it"!

I thought it would be good to have a thread on this forum that can be used as a sounding board before I get things totally wrong!!

The reason for this post is that I have a new vehicle on order which I am going to be using as a "Demonstrator" for some kit that my company sells and installs in the marine leisure industry. It turns out that there are loads of differences between boats and vans!.........Smart alternators, 12 volts (Who thought that was better than 24V!), massive conducting body shell, etc.

I thought I'd kick off my thread with a diagram of how i intend on "Doing it”.

Not too sure why I’m questioning this but I’m not sure about the use of a smart shunt when all the negs are running off to the chassis. I have simply taken the shunt to ground and then also grounded the main neg bus to the chassis and I am confident that this is right, but boats don't have a convenient metal body to use as a gigantic bus bar. Can I check that this is the correct thing to do with one of the "Gurus" on here?

Notes that help explain oddities in my schematic:

A. The water heater is to only run on twelve volts (from the leisure battery) when the following criteria is met:

1. Engine is running and leisure battery is charging through DC DC charger.

2. More than 10% of water in FW tank.

3. Leisure battery is more than 50% charged (Or whatever other percentage is chosen after install.)

Or

Solar input exceeds 20A and battery charge is greater than 70% (or whatever other percentage is chosen after install.)

B. There is an isolated regulated 12v supply for sensitive electronics and also to stop regular faffing around with fuse of the Wallas hob when the voltage falls slightly under 12.6volts. (Couldn’t Wallas fit a voltage stabiliser theirselves to improve the reliability of their otherwise excellent kit?)

The rest seems pretty self explanatory, but if anyone has any better ideas or any suggested changes I'd love to know?

I would rather know that I have a poor design now than after installing all of the kit, so hoping I may get some constructive feedback:

The front end of the installation, including 400W of solar and DC-DC Charger and Lithium battery under the drivers seat. Note the Smart Shunt being taken straight to the body of the vehicle. This is the bit that is alien to me!

Attachments

Last edited by a moderator: