I've posted a few times before and read a huge amount of helpful stuff on here - thank you all!

I thought it might be worth me setting up a thread for my build because I keep forgetting what I've posted or not. I'm converting a 2017 sub T6 - my first time and I'm trying to do much of the work myself.

First job was getting the pop top installed by Westdubs in January - I went to their warehouse near Malvern and they were absolutely brilliant, so helpful and threw in extra little things for free, even carpeting a spare bit of wood for me and was a really reasonable price. So thanks guys - strongly recommend.

Other stuff I have done already:

Bulkhead

strip ply and floor

cut out the windows with angle grinder and jigsaw - installed Kiravans windows. Made quite a lot of mistakes here including not protecting them from swarf which has marred the rear windows a bit, and I'm still dealing with a tiny leak in one. - using gorilla pour and seal to fix hopefully!

Fitted a MS Craft Swivel seat

Sound deaden and insulate the walls.

Carpet line around the pop top.

carpet wheel arches etc.

Having trouble pinning down an rnr bed supplier - after one of them went silent on me (still owes me £347 and I am having to raise a dispute with PayPal )

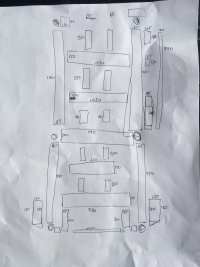

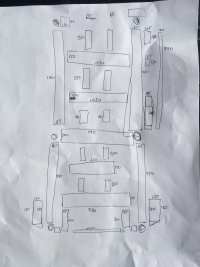

Today I fitted my floor. Measuring the batons and cutting them took a looooong time. Here's my paper plan in case it helps anyone.

I used 9mm ply for batons and for the floor. I cut the floor with a jigsaw in two pieces - its alright.

Stuck the batons down with sikaflex.

10 sheets of Dodo hex in the gaps.

I had a couple of sheets of insulation left over so I spent a ridiculously long time cutting into thin strips and filling the gaps in lots of the ridges which I'm sure will have very little effect, but waste not want not.

Stuck the ply floor down on top of that. Sikaflex and no more nails when I ran out.

Then I remembered that I was going to wait until the vinyl arrived so I could use the floor as a template....whoops.

I thought it might be worth me setting up a thread for my build because I keep forgetting what I've posted or not. I'm converting a 2017 sub T6 - my first time and I'm trying to do much of the work myself.

First job was getting the pop top installed by Westdubs in January - I went to their warehouse near Malvern and they were absolutely brilliant, so helpful and threw in extra little things for free, even carpeting a spare bit of wood for me and was a really reasonable price. So thanks guys - strongly recommend.

Other stuff I have done already:

Bulkhead

strip ply and floor

cut out the windows with angle grinder and jigsaw - installed Kiravans windows. Made quite a lot of mistakes here including not protecting them from swarf which has marred the rear windows a bit, and I'm still dealing with a tiny leak in one. - using gorilla pour and seal to fix hopefully!

Fitted a MS Craft Swivel seat

Sound deaden and insulate the walls.

Carpet line around the pop top.

carpet wheel arches etc.

Having trouble pinning down an rnr bed supplier - after one of them went silent on me (still owes me £347 and I am having to raise a dispute with PayPal )

Today I fitted my floor. Measuring the batons and cutting them took a looooong time. Here's my paper plan in case it helps anyone.

I used 9mm ply for batons and for the floor. I cut the floor with a jigsaw in two pieces - its alright.

Stuck the batons down with sikaflex.

10 sheets of Dodo hex in the gaps.

I had a couple of sheets of insulation left over so I spent a ridiculously long time cutting into thin strips and filling the gaps in lots of the ridges which I'm sure will have very little effect, but waste not want not.

Stuck the ply floor down on top of that. Sikaflex and no more nails when I ran out.

Then I remembered that I was going to wait until the vinyl arrived so I could use the floor as a template....whoops.