So bear with me.

Been looking at getting this (btw, any thoughts on how good these ones are where the wires are discreetly positioned under the back of the panel?): Solar Technology – 150 Watt Flexi Solar Panel – Black Rear Exit – STPVF150RBS - Batteries and Solar

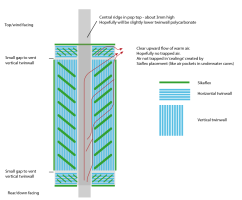

...And after watching people Sika-ing their panels down and creating lots of air pockets/traps/loops with haphazard zig zags and whatnot, it was playing on my mind how best to avoid 'ceilings'/pockets where hot air can get trapped (like airpockets in underwater caves) - given that warm air will travel upwards on a sloped pop top.

Add to that, I was wondering it it would be good to have the twinwall with the vents horizontal - so the entire sides can vent and there's actually more entries and exits for airflow, not sealing the edges closed with sika. But I wonder if the wind going down all those open holes would create drag/vortexes that would actually pull at the panel as the air rushes by.

So attached is my compromise to deal with both the above thoughts:

Yes I think i have ADHD. Yes I may be over thinking this - but just have to, cuz it's what i do!!

TL R: I'm driving myself mad over analysing Van additions...as usual

R: I'm driving myself mad over analysing Van additions...as usual

Been looking at getting this (btw, any thoughts on how good these ones are where the wires are discreetly positioned under the back of the panel?): Solar Technology – 150 Watt Flexi Solar Panel – Black Rear Exit – STPVF150RBS - Batteries and Solar

...And after watching people Sika-ing their panels down and creating lots of air pockets/traps/loops with haphazard zig zags and whatnot, it was playing on my mind how best to avoid 'ceilings'/pockets where hot air can get trapped (like airpockets in underwater caves) - given that warm air will travel upwards on a sloped pop top.

Add to that, I was wondering it it would be good to have the twinwall with the vents horizontal - so the entire sides can vent and there's actually more entries and exits for airflow, not sealing the edges closed with sika. But I wonder if the wind going down all those open holes would create drag/vortexes that would actually pull at the panel as the air rushes by.

So attached is my compromise to deal with both the above thoughts:

- There's a shallow ridge down the centre of my pop top which i hope to raise the panel up off of using thicker twinwall than the height of the ridge, and have no Sika here at all - reason being is all that central section would be prone to overheat if stuck down to the poptop, as though i wasn't using twinwall at all. It will also create a great amount of airflow upwards when at rest, but not much windflow downwards when driving due to the shielded entry at the front , see next point (i hope)

- Front of the panel that takes the brunt of the wind force when driving, is fully sealed off.

- Then there's a small section of horizontal twinwall, to allow for a good amount of exit space for hot air, but hopefully not much of an easy entry for wind (probaly would pull air OUT of this section as the air rushed by)

- Then the most part would be vertical twinwall, with plenty of area to anchor with Sika

- Then a small section of horizontal twinwall to give nice entry for cool air, thus creating a chimney effect across the entire construction - cool air into bottom, hot air out of top.

- Note the gap in sika right at the bottom centre where the ridge is - this is to allow even more cool air up/allow good exit for windflow when driving

- The sika shown is the sika used between the solar panel and the twinwall (the sika for the twin wall to the poptop would be put on using upward facing diagonals similar to the main section in the diagram - again allowing for no places for any hot air to get trapped even under the twinwall)

- Once the panel is flattened and the Sika spreads, there will be be very tiny gaps/channels where there is no sika, where hot air can flow up and away.

Yes I think i have ADHD. Yes I may be over thinking this - but just have to, cuz it's what i do!!

TL