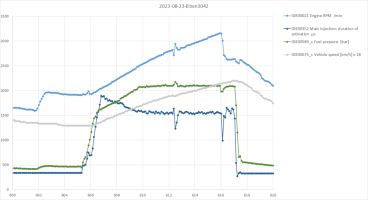

Morning MMI,I'm not sure. I'll do similar runs with mine (same CXEB engine) to get more data. A 30 minute capture today didn't have any of the drop-outs with these - but I didn't push it that much.

IDE07785 Turbine actuator 1 bank 1: posit.feedback - Actual valueIDE07793 Turboc.1 turbin.bypass valve 1 B. 1: pos.feedback - Actual valueIDE08138 Bypass valve for turboch 2 turbine inlet: activation

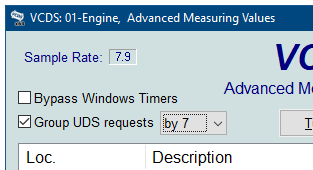

I've ordered a new VCDS Hex-V2 cable, should be here tomorrow. So I'll get a new log file once it's here, so that we can look at data with a decent logging rate.

Just thinking about the 3 channels dropping out, I'm trying to understand what could cause that. It's unlikely that all 3 solenoid valves would fail at the same time, so they must be being driven/controlled from another sensor? Something like the G31 sensor in the thread you linked earlier? I am not sure on the setup of these systems! But it sounds like from what you've seen, these 3 channels should not be dropping out like that under acceleration?