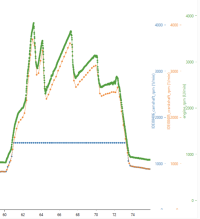

I always love some detective work and theories!I wonder if this clipping is to do with the sampling rate of the ECU topping out. 60 teeth on the disc on the end of the shaft, at 1400rpm, it needs to sample to find the on and off edges of the signal, so it makes sense that the sampling resolution might be, say, 20 samples per tooth. At 1400 rpm that’s 28khz.

There's other things wrong with that signal - cam speed is 1/2 of crank speed in all 4-stroke engines so it's not anyway matching the physical realm