Ok I am now up to the stage of buying the ply panels and carpet.

Ply Panels

Options

Floor: 12mm or 9mm.

12mm maybe a bit more solid, disadvantage more weight

9mm maybe a bit flexible, advantage lighter weight

With both will need to think about height and matching the steps.

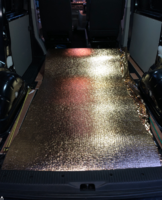

At the moment I have 9mm batons (Silent Coat between) and then some 5mm spongy insulation stuff then they ply floor to go on this.

Sides:

6mm or 3.6mm

Custom shop designs suggested 3.6mm was fine unless I planned to put any speakers in then go for 6mm. Is this the way to go? Or can I get away with 3.6mm and mount speakers (not going to at the moment but what if in the future?)

Carpet:

I have read on hear about jointless (1 piece carpet), especially on the awessome work by @Absolut5 but Harrisons said with 2 m width carpet its not possible to line the back of a SWB panel van only using 1 piece. Is this correct?

If not where would the carpet start?

Secondly, if I wanted to do 1 colour carpet how many meters would I need.

Or if I wanted 2 colours 1 for the metalwork and a second for the removable panels how much would I need.

Thanks for any info you can give to help these decisions.

Ply Panels

Options

Floor: 12mm or 9mm.

12mm maybe a bit more solid, disadvantage more weight

9mm maybe a bit flexible, advantage lighter weight

With both will need to think about height and matching the steps.

At the moment I have 9mm batons (Silent Coat between) and then some 5mm spongy insulation stuff then they ply floor to go on this.

Sides:

6mm or 3.6mm

Custom shop designs suggested 3.6mm was fine unless I planned to put any speakers in then go for 6mm. Is this the way to go? Or can I get away with 3.6mm and mount speakers (not going to at the moment but what if in the future?)

Carpet:

I have read on hear about jointless (1 piece carpet), especially on the awessome work by @Absolut5 but Harrisons said with 2 m width carpet its not possible to line the back of a SWB panel van only using 1 piece. Is this correct?

If not where would the carpet start?

Secondly, if I wanted to do 1 colour carpet how many meters would I need.

Or if I wanted 2 colours 1 for the metalwork and a second for the removable panels how much would I need.

Thanks for any info you can give to help these decisions.