Hi guys and gals.

I'm after some help. Before we start any help given that directly results in the rectification of the won't go unrewarded. I have found some forum's (not this one to date) to be against helping businesses as we earn money from fixing these things. Anyway I digress.

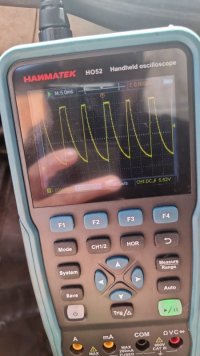

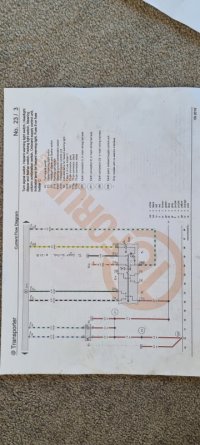

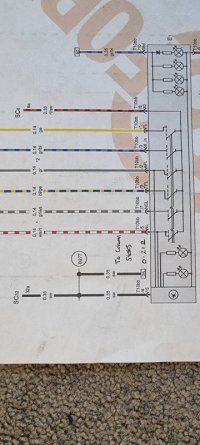

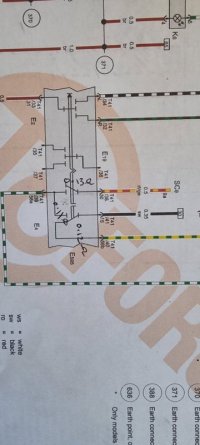

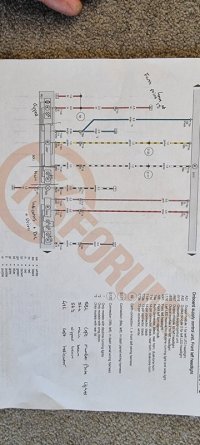

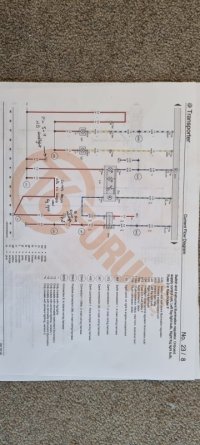

So if you could read through the following post. The vehicle came to me after already having known working lights removed from one vehicle and fitted to this one. This vehicle has LED lights from factory. We tried various things including recoding and Re-Parameterizing the BCM using ODIS which initially appeared to fix it. However a few hours after it leaving the workshop the issue reared it ugly head and we where back to square one. After consulting some wiring diagrams and a few others in the trade I came to the conclusion it must be the BCM as the lights have been replaced. However after changing the BCM and coding it using ODIS this appears to not be the case.

The fault happens in Auto and manual modes on the light switch. There doesn't appear to be a set pattern. It's now driving me, the vehicle dealer and his customer nuts.

ALL HELP WILL BE GREATFULLY RECIEVED!

Many thanks

Chris

Thread 'Blinking/flashing factory LED dipped beam' Blinking/flashing factory LED dipped beam

I'm after some help. Before we start any help given that directly results in the rectification of the won't go unrewarded. I have found some forum's (not this one to date) to be against helping businesses as we earn money from fixing these things. Anyway I digress.

So if you could read through the following post. The vehicle came to me after already having known working lights removed from one vehicle and fitted to this one. This vehicle has LED lights from factory. We tried various things including recoding and Re-Parameterizing the BCM using ODIS which initially appeared to fix it. However a few hours after it leaving the workshop the issue reared it ugly head and we where back to square one. After consulting some wiring diagrams and a few others in the trade I came to the conclusion it must be the BCM as the lights have been replaced. However after changing the BCM and coding it using ODIS this appears to not be the case.

The fault happens in Auto and manual modes on the light switch. There doesn't appear to be a set pattern. It's now driving me, the vehicle dealer and his customer nuts.

ALL HELP WILL BE GREATFULLY RECIEVED!

Many thanks

Chris

Thread 'Blinking/flashing factory LED dipped beam' Blinking/flashing factory LED dipped beam