You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Help please Flashing coil light and EML on. Multiple codes 31391 27202 8208 8216 8217 8338

- Thread starter Westcoast888

- Start date

-

- Tags

- fault codes

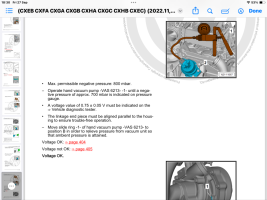

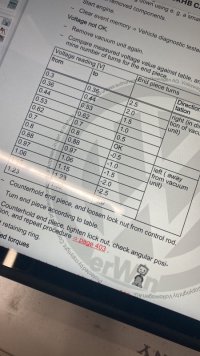

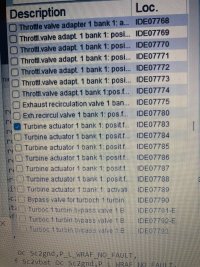

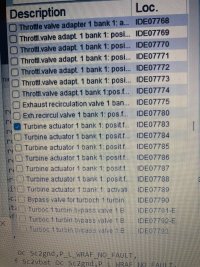

to check the voltage I opened vcds and then the engine controller. I selected output tests and then turbine actuator IDE07783. I figured this out by myself so it might not be correct but the voltage value changed as I operated the actuator with the mityvac gan

The N/A value will change as you move the actuator.

The N/A value will change as you move the actuator.

.

fingers crossed I got it right!

The N/A value will change as you move the actuator.

The N/A value will change as you move the actuator..

fingers crossed I got it right!

Stuffed some blue rag in the air pipes in readiness for the flying circlips!

But to be fair it wasn’t too bad and I had success with the 2nd one. God knows where the first one went! Trying to keep the mityvac pumped while manoeuvring some long handled pointy nose pliers with a small screwdriver in your third hand is tricky enough especially in a dark space with crap eyesight!

Last edited:

Yes, I believe so.fingers crossed I got it right!

Just to complement - another way to access would beto check the voltage I opened vcds and then the engine controller. I selected output tests and then turbine actuator IDE07783.

VCDS > Select > 01-Engine > Adv. Meas. Values > then pick IDE07783

I’m out of MOT atm so just got to change the rear discs and pads and then go for test. I’ll then do a road test and log the values to make sure the turbos are boosting ok. If everything is ok I’ll wrap this up. Hopefully the thread will help others in the future.

Massive thanks to @mmi for all the help in getting to the bottom of it.

Massive thanks to @mmi for all the help in getting to the bottom of it.

so how did you get on?

...

@rajjinator is doing the same job and is having some issues with the actuator length. . .

www.t6forum.com

www.t6forum.com

.

...

@rajjinator is doing the same job and is having some issues with the actuator length. . .

P00AF - 'stuck' with new turbo

Hi all, I have just fitted a new turbo from London Turbos and am getting a fault relating to the actuator position. It's actually in a Crafter, but it's a DAUA engine so relevant in all areas I guess so posting here for better visibility. To cut a long story short, the turbo has been replaced...

.

Sorry for the delay. I’ve changed the rear brake discs and pads, then taken the van for an MOT. It passed with no advisories but I’ve been so busy since I haven’t had the time to take it for a drive. Was hoping to hook up the laptop with vcds on its first test run just to make sure it’s boosting properly. I’ll get to it as soon as poss!so how did you get on?

...

@rajjinator is doing the same job and is having some issues with the actuator length. . .

P00AF - 'stuck' with new turbo

Hi all, I have just fitted a new turbo from London Turbos and am getting a fault relating to the actuator position. It's actually in a Crafter, but it's a DAUA engine so relevant in all areas I guess so posting here for better visibility. To cut a long story short, the turbo has been replaced...www.t6forum.com

.

@Westcoast888 how tricky was this and why do you need the vac unit? It looks like my actuator has died as well...View attachment 260838

Stuffed some blue rag in the air pipes in readiness for the flying circlips!

But to be fair it wasn’t too bad and I had success with the 2nd one. God knows where the first one went! Trying to keep the mityvac pumped while manoeuvring some long handled pointy nose pliers with a small screwdriver in your third hand is tricky enough especially in a dark space with crap eyesight!

Is it just the charge cooler that needs moving to get access?

Thanks

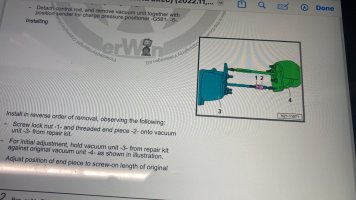

Sorry for the late reply. It was reasonably straightforward once the fault had been diagnosed. @mmi was very helpful in pointing me in the right direction on more than one occasion. You need the vac gun to operate the actuator to remove it and also to calibrate the new one. Worth buying one as they are very handy for other jobs such as bleeding brakes etc. also worth becoming a member so you can download the workshop manual. I’ve got an old laptop in the workshop loaded with the manual so it’s easy to refer to. I then use my day to day laptop for vcds.@Westcoast888 how tricky was this and why do you need the vac unit? It looks like my actuator has died as well...

Is it just the charge cooler that needs moving to get access?

Thanks

Great result, and thanks for the detailed write up. I may need it it sometime ( but hopefully not too soon though)Sorry for the late reply. It was reasonably straightforward once the fault had been diagnosed. @mmi was very helpful in pointing me in the right direction on more than one occasion. You need the vac gun to operate the actuator to remove it and also to calibrate the new one. Worth buying one as they are very handy for other jobs such as bleeding brakes etc. also worth becoming a member so you can download the workshop manual. I’ve got an old laptop in the workshop loaded with the manual so it’s easy to refer to. I then use my day to day laptop for vcds.

Big shout out to MMI also, who is always a big help.

Thanks. I bit the bullet and had VW change the turbos. Just didn’t have the time or head space to sort it out myself. It financially hurt but the van was fixed within a week.Sorry for the late reply. It was reasonably straightforward once the fault had been diagnosed. @mmi was very helpful in pointing me in the right direction on more than one occasion. You need the vac gun to operate the actuator to remove it and also to calibrate the new one. Worth buying one as they are very handy for other jobs such as bleeding brakes etc. also worth becoming a member so you can download the workshop manual. I’ve got an old laptop in the workshop loaded with the manual so it’s easy to refer to. I then use my day to day laptop for vcds.

Thanks

Similar threads

- Replies

- 5

- Views

- 710

- Replies

- 0

- Views

- 587

- Replies

- 5

- Views

- 771

- Replies

- 12

- Views

- 3K