Thanks. Not sure really where to go then, as I don’t know the pump they fitted isn’t faulty, so to ask them to fit another is just me guessing, so I am sure they won’t cover the cost. Not sure how to get around that? It’d be another £300 plus bill to perhaps only discover it wasn’t the pump again.

I probably need someone who can test the ecu signal wire with proper kit? As I only have a volt meter. Not sure how the pump can be tested, as it clearly powers up and runs, so idk how I could prove the pumps circuit board or whatever is at fault as is.

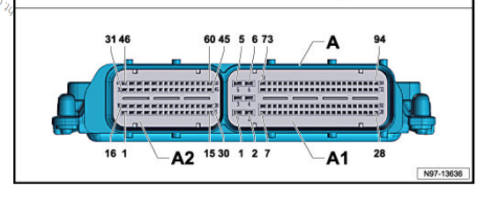

I looked at the end of the ecu connector, after a bit of a fight getting the purple locking tab back in, it looked as though all pins were seated ok, although some did look a bit wonky compared to others.

I guess to test the pump theory I maybe need a known good one to connect outside the system to see if the fault returns or not? Assume it shouldn’t do any damage if ran with ignition on only (engine not running)? Is that an idea? Although where would I get a known good pump from to test :/

I can pull the battery out and check the wire didn’t get snagged behind the battery, I put it in one of those hard plastic corrugated sleeves to protect it. The battery install did squash the casing a bit in the corner where it comes out, but I checked and it didn’t look anywhere near enough to actually crush the one small wire inside.

I didn’t fit an entirely new wire with new pin in the connector, I assumed the wire at the ECU end was not the problem as it was not broken and did not look worn.

All this time when I was testing at the weekend, I could clear the error, where it would not come back for several mins or perhaps until a start cycle and engine running. It was not present 100% of the time. So seems to be an intermittent fault.

But it looks like once it appears as a static error, priority 2 once, it will not go by itself back to intermittent and must be cleared.

If it was the ECU, would we not expect other faults to crop up?

I’m just getting tired of it now, spent about £500 and two whole weekends on this problem, and seem to still be no further forward :/