Thanks - the available functions are (obviously) specific to engine type -I took pictures with my phone of the options in "Output test" and Basic Settings" because the drop down menu closed on me when trying to sceenshot it.

There is a test "Auxiliary Fuel Pump (FP) Relay". Also in Basic settings there is "Test of auxiliary fuel pump"

Unfortunately I don't know what to expect about these tests - and how to measure their output by VCDS. I'd guess it's worth trying what those tests tell?

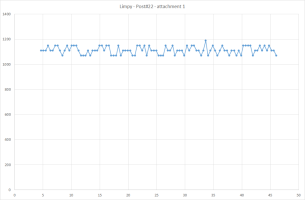

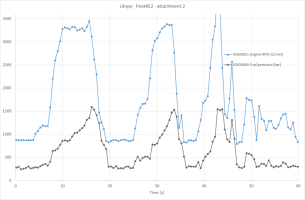

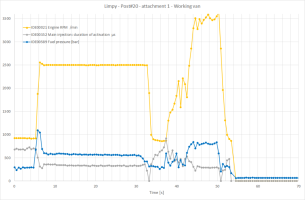

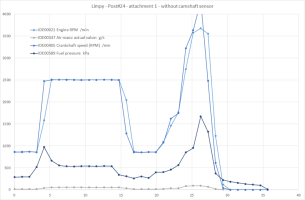

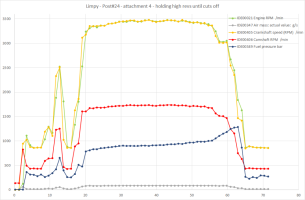

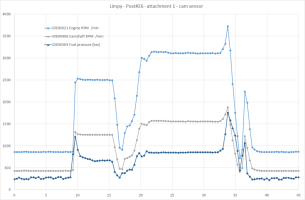

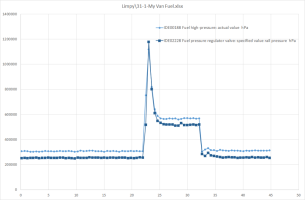

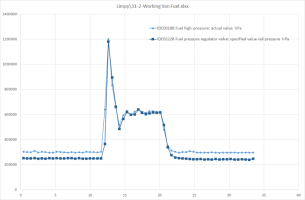

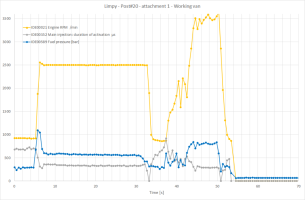

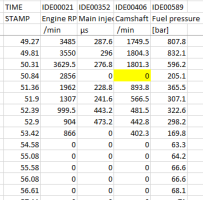

Anyways, the data capture from working van below. Everything seems to be as expected - no fuel pressure build up.

However, an interesting dip at 50.84 seconds in camshaft RPM. Otherwise follows engine RPM (divided by 2). Possibly because of "forced" shutdown just causing data loss.

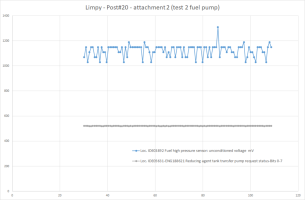

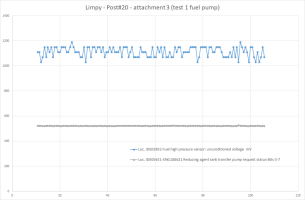

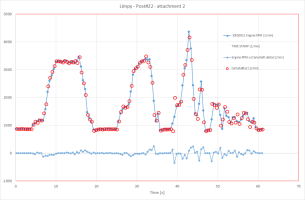

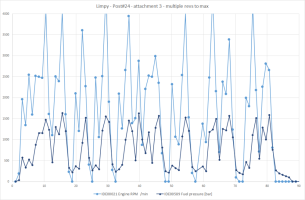

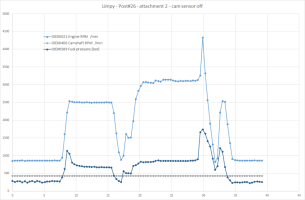

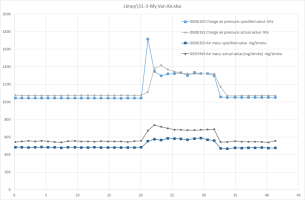

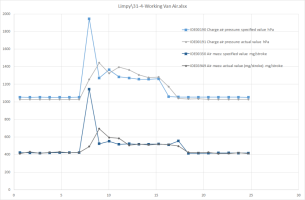

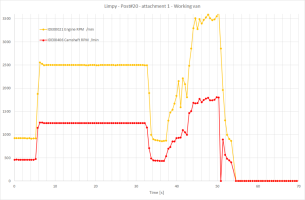

Then I'm afraid fuel pump tests didn't produce anything useful - no real change detected in fuel high pressure sensor data. Just flat curves. Also the grey one "Reducing agent tank" shouldn't be relevant to your van.