Creating this thread to share photos on progress of the build and to share ideas. Been reading this thread and learning all I can as well as incorporating my experience of remote Overlanding around the African continent over the past 15 years. The build is leaning towards an offroad capable, offgrid ready yet comfortable daily driver. I am originally from South Africa and living/ working in Europe (My parents are from Poland).

The Planned Build:

The Van itself is a LHD, 2019 T6 2.0 TDI 4Motion, Manual, Dual Door, Tailgate, Nordic kit, ACC, MSFW, Heated Seats. 175,000km on the odo.

This is the van when I picked it up. It was purchased on 18 November 2024.

The first mod done: I then fitted some nice 18" Alloys + Winter tyres and removed the roof rack as I don't use it. I have sent it in for a complete service; all the oils and fluids have been changed, gearbox oil flushed, all filters changed, new Brembo discs and pads and new battery.

I will continue to update this thread on my build as I go.

The Planned Build:

- Swamper Alloys + AT Tyres (Summer wheels) - These will likely be 17"... Maybe an 18" depending if they will fit.

- 18" Winterwheels (Kumho WinterCraft 235/55/18)

Fitted

Fitted - Bravo Snorkel

- 45mm Lift

- Digital Instrument Cluster

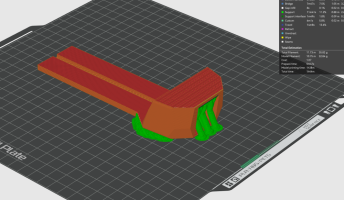

- Smart Rear view mirror (I will 3D print a holder for the rear camera and will stick it to the top of the Tailgate)

Fitted

Fitted - Pop Top tent (Undecided on brand at the moment)

- 2 x 120W Semi-flex Solar Panels on the roof

- Kitchen Unit + Domentic Sink/ Gas hob + Fridge

- Safari Style popup windows on both sides

- Glass install on rear quarter windows, Fake window on the back

- Vamoose Awning Rail + Frontrunner Pull out awning with sides

- 3/4 Rock n Roll bed

- Bonnet mount Solar Panel

- Underbody Water tank

- Underbody Fuel Tank

- Underbody Protection

- Spotlights / Lazer lamps

- Spare wheel carrier

- Change all engine bay piping to silicone

The Van itself is a LHD, 2019 T6 2.0 TDI 4Motion, Manual, Dual Door, Tailgate, Nordic kit, ACC, MSFW, Heated Seats. 175,000km on the odo.

This is the van when I picked it up. It was purchased on 18 November 2024.

The first mod done: I then fitted some nice 18" Alloys + Winter tyres and removed the roof rack as I don't use it. I have sent it in for a complete service; all the oils and fluids have been changed, gearbox oil flushed, all filters changed, new Brembo discs and pads and new battery.

I will continue to update this thread on my build as I go.

Last edited:

.

.