steve@helixcabinetmakers.

New Member

I had an issue with cylinder 1 glow plug on CXHA engine.

Replaced all 4 glow plugs yesterday.

To try and make my life a little bit easier, I remove the fuel rail for access to the glows.

I have Carista which has a fuel system prime function.

Carista say, to be used when replacing injectors or working on the fuel system.

Tested this first and the lift pump runs for 3 minutes.

Also whilst running Carista I disconnected all 4 fuel line connectors one at a time.

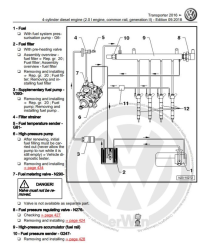

I have fuel going to the high pressure pump and back to the tank and in and out of the filter.

From what i know the high pressure pump is driven by the cambelt.

Does the fuel rail and high pressure pump need to be primed before cranking the engine.

At the moment the engine will not start and i am worried about damaging the high pressure pump.

Does VCDS do more than just run the lift pump.

If anyone can help it would be most appreciated.

Thankyou.

Replaced all 4 glow plugs yesterday.

To try and make my life a little bit easier, I remove the fuel rail for access to the glows.

I have Carista which has a fuel system prime function.

Carista say, to be used when replacing injectors or working on the fuel system.

Tested this first and the lift pump runs for 3 minutes.

Also whilst running Carista I disconnected all 4 fuel line connectors one at a time.

I have fuel going to the high pressure pump and back to the tank and in and out of the filter.

From what i know the high pressure pump is driven by the cambelt.

Does the fuel rail and high pressure pump need to be primed before cranking the engine.

At the moment the engine will not start and i am worried about damaging the high pressure pump.

Does VCDS do more than just run the lift pump.

If anyone can help it would be most appreciated.

Thankyou.