So the time has come to convert my LWB 2015 T6 into a camper. I have owned it for the last 5 years, it's had a very easy life and has only racked up 31k on the clock.

I have been reading build logs and a large number of posts to learn, get up to speed, and make myself aware of the many many options there are. I hope by documenting the build here, it will be helpful for others, even if I post mistakes it'll act as a 'what not to do guide'.

A scope of the planned work is:

Westdubs black pop top with yellow scenic canvas

Dark tint windows for all rear doors and panels (fake rear quarter drivers side)

Jac conversions 3/4 width R&R bed with easy slide mech

Insulation and full rear carpet lining in silver grey

Possibly veneered panels on the underside of the pop top bed and kitchen splashback

Floor insulation, 9mm ply, vinyl flooring

Planar 2D diesel air heater

57 wheel arch water tank, shurflo pump, no waste water tank

Underslung Propex LPG tank with bbq point

Camplux shower at rear (makeshift cubicle utilising barn doors)

Smev 9222 or 9722 gas hob, florenz tap

JustKampers JKF50 fridge

Electrics:

I have been reading build logs and a large number of posts to learn, get up to speed, and make myself aware of the many many options there are. I hope by documenting the build here, it will be helpful for others, even if I post mistakes it'll act as a 'what not to do guide'.

A scope of the planned work is:

Westdubs black pop top with yellow scenic canvas

Dark tint windows for all rear doors and panels (fake rear quarter drivers side)

Jac conversions 3/4 width R&R bed with easy slide mech

Insulation and full rear carpet lining in silver grey

Possibly veneered panels on the underside of the pop top bed and kitchen splashback

Floor insulation, 9mm ply, vinyl flooring

Planar 2D diesel air heater

57 wheel arch water tank, shurflo pump, no waste water tank

Underslung Propex LPG tank with bbq point

Camplux shower at rear (makeshift cubicle utilising barn doors)

Smev 9222 or 9722 gas hob, florenz tap

JustKampers JKF50 fridge

Electrics:

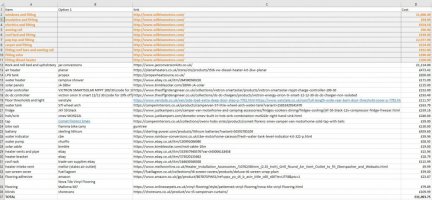

- Sargent EC155 power supply unit

- JA solar 380w panel

- Victron Orion tr Smart 12/12-30 dc-dc charger

- Victron Smart Solar 30/100

- Sterling Power 100ah LiFePO4 battery