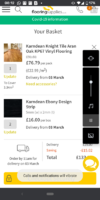

Putting in an order for my floor today so no pics as yet but will be coming soon!

I've seen some great floors (@Ads_Essex , @JaySal, @Rapt0rUK ) from other threads and thought be good to pull them together and be a good place to post advice/tips in one easy to find place.

I've seen some great floors (@Ads_Essex , @JaySal, @Rapt0rUK ) from other threads and thought be good to pull them together and be a good place to post advice/tips in one easy to find place.

Last edited: