How-to:

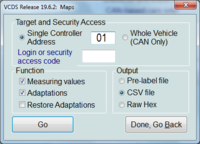

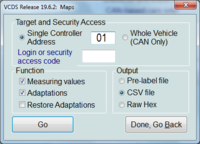

VCDS -> Applications -> Controller Channel Map ->

Tick/fill boxes as above and hit Go

VCDS Flashes screens for a moment (when finished hit "Done, Go Back") and there will be files adpmap-01-... and blockmap-01-... in directory C:\Ross-Tech\VCDS\Logs\....

Just strip off last 5 digits of the VIN (if so desired) in file name an upload the files here.

EDIT: Just realized - the VIN in the blockmap - first line of data!

-----------------------------

For the comparison - I have just used Excel, just copy column 3 from the suspect and paste to "original", however as there might be some missing/additional "channels" because of different ECU software - need to keep eye on the alignment.

Anyways, I'm more than happy (and curious ) to do that here "online"

) to do that here "online"

VCDS -> Applications -> Controller Channel Map ->

Tick/fill boxes as above and hit Go

VCDS Flashes screens for a moment (when finished hit "Done, Go Back") and there will be files adpmap-01-... and blockmap-01-... in directory C:\Ross-Tech\VCDS\Logs\....

Just strip off last 5 digits of the VIN (if so desired) in file name an upload the files here.

EDIT: Just realized - the VIN in the blockmap - first line of data!

-----------------------------

For the comparison - I have just used Excel, just copy column 3 from the suspect and paste to "original", however as there might be some missing/additional "channels" because of different ECU software - need to keep eye on the alignment.

Anyways, I'm more than happy (and curious

) to do that here "online"

) to do that here "online"

Last edited: