Hi all,

Thought Id start a thread for our T6 that we are converting. Hopefully something shown could help someone and contribute back to the community.

Got this last year second hand 2019 T6 LWB with tailgate.

So far Id installed a westfalia swan neck towbar & planar external diesel heater (which I plumbed into the fuel tank). Id also put in some sound deadener 2mm silent coat & various insulation all from deadening.co.uk.

A few months ago we got SK Conversions to install a Hilo sport 2.0 pop top roof. Super impressed with how low profile it is. will add a photo of it when I finally take one.

Last week I got busy and a mate let me use his workshop so I could install windows, the ply floor, carpet the walls, lay a altro floor, put in a MS Craft swivel passenger seat base, install the starter battery cable through to the DC DC location and wire in a cable for the DC DC to recognise ignition activation. The windows we got from camper glass and impressed with the quality and fit overall.

Used plastic sheet and masked everything up. Then cut out the reinforcement bars in the panels, drilled a whole in the corner and then cut them out. My friend has an air nibbler which was great although it does spit little bits of metal everywhere. A hoover, bag or something to catch them as you go would have been good. I cut them out in 2 passes. Not sure if totally neccessary but some sites say to release tension in the panel by cutting out smaller area first so thats what I did.

Once cut out I filed & treated the edges with some of the primer from the windows pack and on the panels outside for the adhesive. Shold have masked up where I wanted the primer to go as id have got a straighter line not that it matters really as you dont see it.

Then went on the window trims.

I carpeted the inside with 4 way stretch pacific blue from mega van matts. On the whole the carpet install was very easy and went in very smoothly with a professional finish.

I used up the some of the excess insulation on the floor. Not sure how much benefit it is but cant do any harm and probably adds some sound deadening.

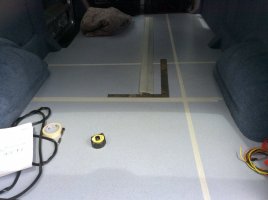

Then went in the one piece ply floor what I also got from SK Conversions. I stuck this down with Tiger seal and lots of weights over the entire floor.

Next was the big one with all the windows going in. This was suprisingly easy. I cut of the nozzel to the middle setting including a peeked notch and my mate had a electric gun which made running a smooth bead pretty effortless. The adhesive held up remarkably well with minimal sag. Masking taped it all up and left overnight. The only window we had trouble with was the tailgate as the window wouldnt sit down properly with the trim in place so we installed it without the trim and ill need to sort something out at a later date to neaten it up.

I then laid the altro flooring down which was painful as always but I got a good finish. I laid it long so that the front edge went under the rear of the front cab rubber floor and the rear long to go under the black tailgate plastic floor edge cover. The altro floor is super tough and seems to have little bits of stone in it or something. Really went through stanley blades. The hooked blades are really helpfull for the install and just go super slowly taking a little at a time.

We wired in the side step light to the roof light connector next. I took the wire under the step & floor then up under the seatbelt trims.

Because I needed to install a sensor wire for the DC DC charger to recognise ignition on I had to take all the dash apart. I found a great instructional video for this that made the process easy. Look on youtube for "How to retrofit VW Transporter T6 Comfort Dash" by Advanced In-Car Technologies. I soldered the sensor wire in to the wire going to the fuse 5th down on the right which only seems to come on with the ignition.

The battery cable and towbar wires I took through a gromet on the front nearside of the engine bay behind the battery compartment. You have to remove the wipers & scuttle tray (this just pulls up) I drilled a hole through the black metal panel behind the battery and then took the cables through the grommet and down into the floor passenger side. The battery cable was 5.5m long and went straight through the middle of the chairs by the handbrake then behind the driver chair to the corner and then ontop of the floor to the rear. It'll eventually get clipped up and hidden behind the units. The towbar wires I had to take across under the dash to the 2 big cable port connectors on the drivers side and solder them onto the apropriate wires. This was a sod as the room/access was minimal but just about doable. I did find 2 of the cables I needed to connect to in the big pile of wires in the centre of the floor which would have been a lot easier to connect to but couldnt find the last one so had to do as per the instructions. Just need someone to come and toggle my towbar flag now so it all works correctly.

Here it is so far.

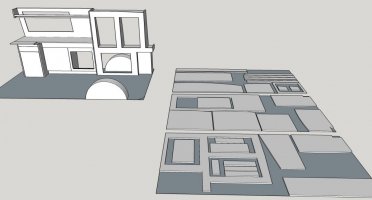

I am now working on the units design & collecting parts to make/install them. I am using sketchup to design it all.

Thought Id start a thread for our T6 that we are converting. Hopefully something shown could help someone and contribute back to the community.

Got this last year second hand 2019 T6 LWB with tailgate.

So far Id installed a westfalia swan neck towbar & planar external diesel heater (which I plumbed into the fuel tank). Id also put in some sound deadener 2mm silent coat & various insulation all from deadening.co.uk.

A few months ago we got SK Conversions to install a Hilo sport 2.0 pop top roof. Super impressed with how low profile it is. will add a photo of it when I finally take one.

Last week I got busy and a mate let me use his workshop so I could install windows, the ply floor, carpet the walls, lay a altro floor, put in a MS Craft swivel passenger seat base, install the starter battery cable through to the DC DC location and wire in a cable for the DC DC to recognise ignition activation. The windows we got from camper glass and impressed with the quality and fit overall.

Used plastic sheet and masked everything up. Then cut out the reinforcement bars in the panels, drilled a whole in the corner and then cut them out. My friend has an air nibbler which was great although it does spit little bits of metal everywhere. A hoover, bag or something to catch them as you go would have been good. I cut them out in 2 passes. Not sure if totally neccessary but some sites say to release tension in the panel by cutting out smaller area first so thats what I did.

Once cut out I filed & treated the edges with some of the primer from the windows pack and on the panels outside for the adhesive. Shold have masked up where I wanted the primer to go as id have got a straighter line not that it matters really as you dont see it.

Then went on the window trims.

I carpeted the inside with 4 way stretch pacific blue from mega van matts. On the whole the carpet install was very easy and went in very smoothly with a professional finish.

I used up the some of the excess insulation on the floor. Not sure how much benefit it is but cant do any harm and probably adds some sound deadening.

Then went in the one piece ply floor what I also got from SK Conversions. I stuck this down with Tiger seal and lots of weights over the entire floor.

Next was the big one with all the windows going in. This was suprisingly easy. I cut of the nozzel to the middle setting including a peeked notch and my mate had a electric gun which made running a smooth bead pretty effortless. The adhesive held up remarkably well with minimal sag. Masking taped it all up and left overnight. The only window we had trouble with was the tailgate as the window wouldnt sit down properly with the trim in place so we installed it without the trim and ill need to sort something out at a later date to neaten it up.

I then laid the altro flooring down which was painful as always but I got a good finish. I laid it long so that the front edge went under the rear of the front cab rubber floor and the rear long to go under the black tailgate plastic floor edge cover. The altro floor is super tough and seems to have little bits of stone in it or something. Really went through stanley blades. The hooked blades are really helpfull for the install and just go super slowly taking a little at a time.

We wired in the side step light to the roof light connector next. I took the wire under the step & floor then up under the seatbelt trims.

Because I needed to install a sensor wire for the DC DC charger to recognise ignition on I had to take all the dash apart. I found a great instructional video for this that made the process easy. Look on youtube for "How to retrofit VW Transporter T6 Comfort Dash" by Advanced In-Car Technologies. I soldered the sensor wire in to the wire going to the fuse 5th down on the right which only seems to come on with the ignition.

The battery cable and towbar wires I took through a gromet on the front nearside of the engine bay behind the battery compartment. You have to remove the wipers & scuttle tray (this just pulls up) I drilled a hole through the black metal panel behind the battery and then took the cables through the grommet and down into the floor passenger side. The battery cable was 5.5m long and went straight through the middle of the chairs by the handbrake then behind the driver chair to the corner and then ontop of the floor to the rear. It'll eventually get clipped up and hidden behind the units. The towbar wires I had to take across under the dash to the 2 big cable port connectors on the drivers side and solder them onto the apropriate wires. This was a sod as the room/access was minimal but just about doable. I did find 2 of the cables I needed to connect to in the big pile of wires in the centre of the floor which would have been a lot easier to connect to but couldnt find the last one so had to do as per the instructions. Just need someone to come and toggle my towbar flag now so it all works correctly.

Here it is so far.

I am now working on the units design & collecting parts to make/install them. I am using sketchup to design it all.