Yes it is my second camper but the title of the thread was more in tune with Blur's "Song 2" WooHoo and all that or possibly I need my head checking!!

So for anyone who has not read my other posts on the forum this camper is to replace our beloved Type 2 Bay window which is currently for sale because we are looking after my mother who has dementia and we are basically housebound. The bay like to be used not just left sat there, also I have had to leave work to look after her so I need to consolidate my vehicles into one to save money as my sole income is a massive £62.70 a week carers allowance. so without further ado here is the old bay window that has served us so well

Once the decision had been made I found a T6 in the VW dealers in Llandudno Junctiom went to see it and bought it, she is a September 2015 102PS Highline with a Euro 6 engine

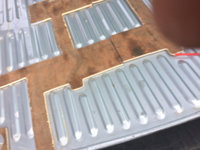

The first job was to rip the ply lining out, then remove the bulkhead (what a PITA that was) befor giving the inside a real good clean. I then ordered some 3.5mm ply for the panels and some 12mm ply for the floor. I used the existing panels as a template for the new ones using a bearing guided router cutter to follow the shape exactly.

We had eventually decided to have lowline cabinets rather than a wardrobe similar to what we have and like in our Bay. This obviously meant that we could have windows all round, my wife also wanted light green glass rather than the more usual 70-80% dark tint, these we eventually found and ordered. We also ordered a Streamline Easylift R&R bed (only 2 of us and we didn't need an M1 tested one), some blue 4 way stretch carpet lining, a Virtfrigio fridge and a Smev 9222 sink/hob, insulation and some Altro non slip flooring.

So for anyone who has not read my other posts on the forum this camper is to replace our beloved Type 2 Bay window which is currently for sale because we are looking after my mother who has dementia and we are basically housebound. The bay like to be used not just left sat there, also I have had to leave work to look after her so I need to consolidate my vehicles into one to save money as my sole income is a massive £62.70 a week carers allowance. so without further ado here is the old bay window that has served us so well

Once the decision had been made I found a T6 in the VW dealers in Llandudno Junctiom went to see it and bought it, she is a September 2015 102PS Highline with a Euro 6 engine

The first job was to rip the ply lining out, then remove the bulkhead (what a PITA that was) befor giving the inside a real good clean. I then ordered some 3.5mm ply for the panels and some 12mm ply for the floor. I used the existing panels as a template for the new ones using a bearing guided router cutter to follow the shape exactly.

We had eventually decided to have lowline cabinets rather than a wardrobe similar to what we have and like in our Bay. This obviously meant that we could have windows all round, my wife also wanted light green glass rather than the more usual 70-80% dark tint, these we eventually found and ordered. We also ordered a Streamline Easylift R&R bed (only 2 of us and we didn't need an M1 tested one), some blue 4 way stretch carpet lining, a Virtfrigio fridge and a Smev 9222 sink/hob, insulation and some Altro non slip flooring.